Your Premier Custom Leather Bags Manufacturer

Turning creative visions into high-quality leather bags is our expertise. Your brand benefits from our strategic factories in Cambodia and China, a resilient supply chain capable of producing over 850,000 bags monthly for the world’s leading fashion names. From initial design to global delivery, we provide a complete, end-to-end service, positioning ourselves as the trusted partner behind your next best-selling collection.

Trusted By:

Full-Service Leather Bags Manufacturing for Your Collection

Finding the right styles is key for your brand, and we are here to make that happen. As a leading leather bag factory, we are experts at creating a huge range of handbag designs. We combine the skill of our talented craftspeople with the power of modern machines. This allows us to build anything you can imagine—from large, structured totes perfect for daily use to small, detailed cosmetic bags for your accessory line. Below, you’ll find the core styles we master every day for our clients.

A perfect mix of style and practicality. We build strong, roomy totes. They have reinforced handles and smart pockets inside. They are great for work, travel, or everyday use.

These bags are made for modern, busy lives. We focus on making them light, comfy, and secure. They have adjustable straps and high-quality metal parts.

We make backpacks for everyone. You can get a sleek, simple one for work in the city. Or you can get a tough one with many pockets for travel. They all look great and are built to last.

This is a style that never gets old. We make beautiful shoulder bags that are easy to carry. We make sure the leather hangs in an elegant way.

Known for their relaxed, crescent shape. We create stylish and roomy hobo bags. They give a chic but casual look. We use soft, flexible leathers for these bags.

This is a trendy, hands-free choice. We make sling bags that fit your body comfortably. They are perfect for city travel and casual fashion brands.

Protect your computer in style. Our laptop bags have special padded sections. They have strong stitching and look very professional for work.

The best bag for a trip or the gym. We build tough duffle bags. They have strong zippers and straps. The inside is big enough to handle any journey.

These small bags are very useful. We create them with beautiful details. They have practical linings and strong zippers. They are perfect for travel sets.

Crafting Every Detail: Your Custom Leather Bag Options

You can customize every single part of your bag. Check out the tabs below. You will see all the options we offer to make a product that is 100% yours.

-

Leather and Materials

-

Textures and Finishes

-

Logo and Branding

-

Hardware and Construction

-

Free Color Choice

Leather and Materials for Making bags

The material is the heart of any great bag. We find the best leathers from top-rated tanneries around the world. What makes us special is our in-house leather finishing facility. This gives us total control over the final color, texture, and quality. We can create the perfect material that matches your brand’s style and needs.

We want to help you make the best choice for your bags. Our team are experts in all types of leather. Below is a detailed guide to the wide range of materials we master.

This is also a fantastic, high-quality choice. We sand the surface a little for a very smooth and uniform look. It’s durable and feels very luxurious.

Best for: Luxury handbags.

While this is real leather, it’s usually made from split-grain that has been heavily processed. We add an artificial grain pattern for a uniform look.

Best for: Mass-market fashion bags.

After splitting a hide, this is the lower layer. While not as strong as the top, it’s very versatile. We often use it to create suede and other textures.

Best for: Suede bags.

You’ll know suede by its signature soft, fuzzy feel. We create this beautiful texture from the hide’s underside, giving a look that feels both casual and stylish.

Best for: Hobo bags.

Nubuck feels soft and velvety like suede, but it’s made from the top-grain layer, which makes it much more durable. It has a refined and luxurious feel.

Best for: High-end casual bags.

This leather is tanned using natural plant materials, not harsh chemicals. It’s known for its classic leather smell and develops a beautiful, dark color as it gets older.

Best for: Eco-conscious brands.

This material is made from leftover leather scraps that are ground up and glued together. It is the most affordable option, but it is also the least durable.

Best for: Low-cost items.

These are high-quality materials made without any animal products. They are perfect for brands that focus on vegan or sustainable lines, available in endless colors and patterns.

Best for: Vegan-friendly collections.

This is an eco-friendly choice made from recycled leather fibers. It provides a sustainable alternative while still offering a genuine leather-like feel, which helps reduce industry waste.

Best for: Eco-conscious brands.

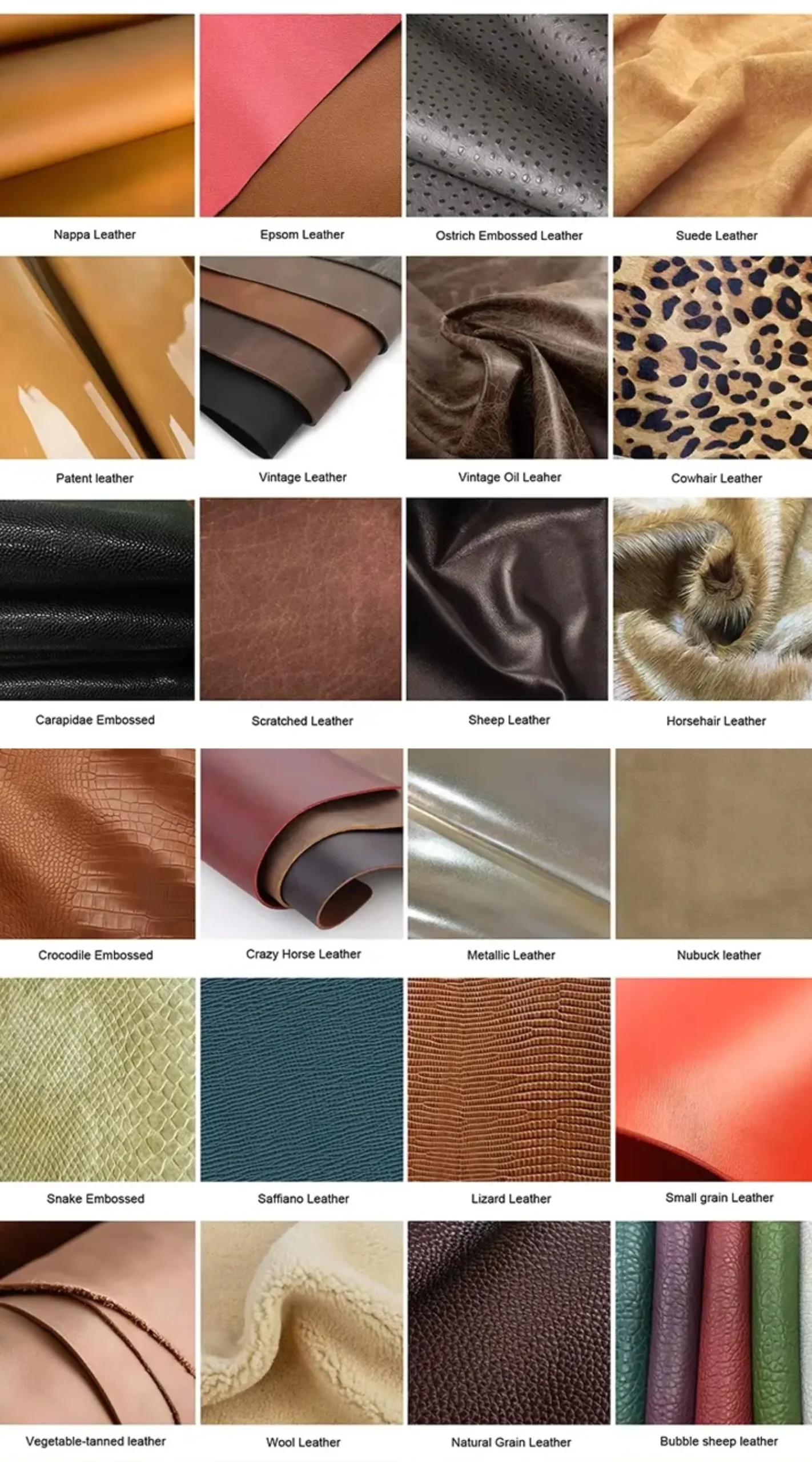

Leather Textures and Finishes For Making Bags

The texture of the leather can totally change a bag’s personality. It’s about how it looks and how it feels. Thanks to our own finishing factory, we are experts at creating amazing surfaces. We can make leather that’s smooth and shiny, or soft and bubbly. We control this process, so you get the exact look you want for your brand.

Our capabilities allow us to create a wide range of popular and bespoke finishes for your collection. We can also develop brand-new, unique textures just for you.

Our Finishing Capabilities Include:

- Natural Grain

- Nappa

- Saffiano

- Pebble Grain

- Ostrich Skin

- Oil wax leather

- Exotic Embossing (Crocodile, Snake, etc.)

- Crazy Horse / Pull-up

- Patent

- Metallic

- Nubuck leather

- Bubble Sheep

- Vegetable-tanned leather

- Wool Leather

- Suede Leather

- Vintage Leather

- Vintage Oil Leaher

- Cowhair Leather

- Horsehair Leather

Logo and Branding for Making Bags

Your brand’s logo is its signature. It tells your story. We offer many ways to put your logo on your bags. We make sure it looks clear, high-quality, and stylish. From a simple stamp on the leather to a custom metal plate, we help you make a lasting impression.

Our experts know both old-school crafts and new technologies. We’ll help you pick the best way to show your brand. We make sure your branding looks great on every single bag.

This is a classic way to press your logo into leather. Embossing makes it raised, and debossing makes it sunken. Both look very classy and feel high-end.

This adds a touch of luxury. We use a heated stamp and a thin sheet of metallic foil (like gold or silver). It creates a shiny, elegant logo impression on the leather.

This is the best choice for logos with many colors or detailed graphics. We use high-quality inks to print your design right onto the material. The creative options are endless.

We use thread to stitch your logo onto the bag. This adds a nice texture and bright colors. It’s a great choice for fabric, canvas, or suede bags.

Give your bag a premium look with a custom metal logo. It can be a small plate or a stud. It’s like adding a piece of fine jewelry to your product.

This gives a modern and often sporty feel. We create a custom mold for your logo in soft rubber. Then, we securely attach the patch to your bag.

This is a separate patch of leather with your logo on it. We then stitch this patch onto the bag. It creates a cool, layered look that stands out.

This is a classic way to show your brand, like on clothes. We make a custom fabric label with your logo. We then stitch it neatly inside the bag for a professional touch.

This is the final, important piece for selling in stores. We can make custom hang tags for you. They can tell your brand’s story and give product info to the customer.

Hardware & Construction For Making Bags

A great bag is more than just beautiful leather. It’s about the small details that make it strong and easy to use. We focus on these details. We use high-quality hardware and expert construction methods. This makes sure every bag we make is built to last.

From the zipper you pull every day to the stitching that holds it all together, we believe in quality you can see and feel.

Premium Hardware Options

The metal parts on a bag are like its jewelry. They must be beautiful and strong. We give you many options:

- YKK Metal Zippers: We use world-class YKK zippers. They are known for being incredibly smooth and reliable. This means no more stuck zippers for your customers.

- High-Quality Metal Alloys: All our hardware, from hooks to rings, is made from durable metal alloys. They have premium finishes that resist chipping and fading.

- Secure Magnetic Buckles: We use strong magnets for our buckles and closures. They snap shut securely and are easy to open. This adds a touch of modern convenience.

- Durable Straps & Hooks: We offer premium leather straps and detachable metal hooks. They are strong enough to carry a heavy load, giving your customers peace of mind.

Built to Last: Our Construction Techniques

How a bag is put together is just as important as the materials. We use proven methods to make every bag super strong:

- Reinforced Handles: Handles are the most-used part of a bag. We reinforce them with extra stitching and internal supports, so they won’t stretch or break.

- Joints with Triple Stitching: At key stress points, like where straps connect to the bag body, we use triple stitching. This makes the joints incredibly strong.

- Rivet Reinforcement: We use metal rivets at corners and strap bases. This not only adds a stylish, rugged look but also provides amazing strength and durability.

- Protective Bottom Rivets: We add “feet” or rivets to the bottom of many bags. This protects the leather from getting scuffed or dirty when placed on the ground.

Color Matching for Custom Leather Bags

Color is everything for a fashion brand. It tells your story and sets the mood. That’s why we offer a free Pantone Color Matching service. We make sure the color of your bags is a perfect match for your brand.

Our color experts can create almost any shade you can dream of. We guarantee the color will be consistent from the first bag to the last. Here’s how our simple process works:

How Our Pantone Matching Service Works:

Step 1: You Give Us Your Code. Just share the official Pantone (PMS) code for your color. This makes sure we are on the same page from the start.

Step 2: We Create a “Lab Dip”. Our team dyes a small piece of your chosen material. This is a test swatch to get the color formula just right.

Step 3: You Approve the Sample. We mail you the physical color sample. You can see and feel the exact color before we start making all your bags.

Step 4: We Match It in Production. Once you say “it’s perfect,” we use that exact formula for your entire order. This guarantees every bag looks exactly the same.

From Concept to Collection: Our Proven Process for Bags

We believe in being open and working as partners. Our simple process makes sure we manage your project perfectly. You will know what is happening at every stage, from the first sketch to the final delivery.

01

Design & Consultation

It all starts with your idea. Show us your designs, sketches, or even just a photo. Our bag experts will talk with you and give you professional advice to make sure your design is perfect for production.

02

Material Sourcing

We create precise digital patterns for your bag. At the same time, we use our global connections and own factory to find the best leather and hardware that match your quality, price, and style.

03

Prototyping & Approval

We then create a physical sample. Our special sample room can make it in just 2-7 days. This lets you check the design, feel the materials, and test the bag before we make the full order.

04

High-Volume Production

After you approve the sample, we start making your full order. Our modern factories in Cambodia and China work fast. Our skilled workers make sure every bag is just as perfect as the sample you approved.

05

Multi-Point Quality Control

Our quality team checks your bags at every single step of the way. We inspect the cutting, the stitching, and the final assembly. We make sure every bag meets your high standards.

06

Packaging & Global Delivery

This is the final step. We handle all the custom packing, labels, and shipping papers. We deliver your finished bags safely to your warehouse, no matter where you are in the world.

Why Choose Hoplok for Leather Bags Manufacturing?

Choosing the right manufacturer is the most important step for your brand. When you partner with us, you get more than just a factory. You get a team of experts with the power, skill, and speed to help your brand win.

- Massive, Reliable Capacity

Your brand can grow without limits. Our factories are built to handle huge orders. We can produce over 850,000 bags every month. This means you can meet your market’s demand with confidence.

- Trusted by Leading Brands

Quality is our promise. The world’s top brands like Calvin Klein and J.Crew trust us with their products. Our factories are fully certified (BSCI, ISO, SMETA), so you know your bags meet the highest global standards.

- Trend-Forward Design Support

Stay ahead of the fashion curve. Our design team based in New York and California knows the latest trends. We help you develop bags that are stylish, modern, and exactly what your customers want to buy.

- Unmatched Speed-to-Market

Launch your new collections faster than your competition. We create high-quality samples in just 2-7 days. Once you approve, our efficient production lines can finish your full order in as little as 15-20 days.

Built to Last: Our Quality & Testing Process

For us, quality is not just a promise—it’s a science. We use a strict, multi-step quality control process. We also have our own lab with advanced machines to test our products. This ensures every bag we make not only looks perfect but is also strong, safe, and built to perform for your customers.

- Raw Material Check: Before we start, we inspect all incoming leather and hardware. We check for any flaws and make sure colors and materials are exactly what you ordered.

- In-Process Check: While we are making the bags, our QC teams are always watching. They check the cutting, stitching, and assembly to fix any small mistakes right away.

- Final Product Check: Before packing, every single finished bag gets a final look-over. We check for perfect looks and strong construction.

- Third-Party Audits: We are confident in our work. We welcome your team or outside experts like SGS and Intertek to come and inspect our factories and products.

- Temperature Tests: We make sure the bag can handle hot and cold weather without damage.

- Scratch Resistance Tests: We test the leather surface to make sure it is durable and won’t scratch easily.

- Tensile Strength Tests: We pull on straps and handles to make sure they are incredibly strong and securely attached.

- Wear & Abrasion Tests: We rub the bag’s surface to simulate long-term use. This makes sure it won’t wear out too quickly.

Frequently Asked Questions

Getting a quote is easy! The best way is to send us an email with as much detail as possible. Here’s what helps us give you an accurate price quickly:

- Your Design: Send us any sketches, photos, or tech packs you have.

- Materials: Let us know what kind of leather or other materials you’re thinking of.

- Quantity: An estimate of how many bags you want to order.

- Size: The approximate dimensions of the bag.

Don’t worry if you don’t have all the details. Just send us what you have, and our experts will guide you through the rest. You can also use the quote form on our website.

We want to help brands of all sizes, from new startups to large retailers. Our usual minimum order for custom bags is 100 pieces per style and color. This is a great number to test a new design in your market without a huge investment. However, we are flexible. If you have a different need, please talk to us. We will always try to find a solution that works for your business.

We are very proud of our speed. Once we have your final design details, our special sample room can create your first physical prototype in just 2 to 7 business days. This is much faster than many other factories. This speed helps you get your product to market faster. You can review the quality and make any final changes quickly before starting the main production.

Our production time is one of the fastest in the industry. After you approve the final sample, a standard bulk order of custom bags is usually completed and ready for shipping in about 15 to 20 days. The exact time can change a little. It depends on how complex your bag design is and how many you order. We will give you a clear timeline when you place your order.

Yes, absolutely! We are more than just a factory; we are your design partner. We have a very talented design team based in the fashion centers of New York and California. They know all the latest market trends. If you only have a basic idea, they can help you develop it into a full, production-ready design. They can create sketches and 3D images to help you see your vision before we even make the first sample.

Ready to Build Your Leather Bags Line?

Let’s talk about your project. Our team of bag manufacturing experts is ready to help you. Contact us today for a free design consultation and a detailed price quote.