Leading Custom Leather Goods Manufacturer for Global Brands – HOPLOK

At Hoplok Leather, a Custom Leather Goods Manufacturer, we bring your brand to life with leather bags, belts, and wallets crafted from high-quality materials in our China and Cambodia factories. From genuine leather shoulder bags to sustainable vegan options, we provide endless choices for colors, textures, materials, and logos—ensuring your products stand out in retail while delivering lasting durability for wholesalers worldwide.

Years of Experience

Skilled Workers

Manufacturing Plants

Companies Served

Bags Produced Monthly

Belts Produced Monthly

Explore Our Custom Leather Goods Range

Hoplok crafts premium custom leather goods with full personalization—from materials like full-grain or vegan to logos via embossing or printing. Our range suits wholesalers and brands, ensuring durable, stylish products that align with retail demands and drive sales growth

From chic totes and crossbody bags to functional laptop cases and backpacks, we manufacture a comprehensive range of custom leather bags. We transform your brand’s vision into reality using premium leathers and meticulous craftsmanship, ensuring each product is built for style, durability, and market success.

A perfect accessory to complete any collection. We specialize in custom manufacturing for both men’s and women’s belts, from classic genuine leather dress styles to modern fashion statements. With endless customization of leathers, hardware, and finishes, we create the ideal belt to elevate your brand.

Where craftsmanship meets function. We produce a full range of custom leather wallets, from minimalist cardholders to classic bifolds and trifolds. Our focus is on the fine details—precision stitching, intelligent layout, and premium materials—to deliver a product that represents your brand’s commitment to quality.

Extend your brand’s story beyond the core collection. We manufacture a wide array of custom small leather goods and accessories, including leather suspenders, keychains, bag charms, custom straps, and more. Let us help you create unique, memorable items that build a complete brand ecosystem and drive customer loyalty.

1,500+Customers in Over 120 Countries & Regions Trust Hoplok

Trust Hoplok Leather as your expert manufacturing partner. We consistently deliver premium custom leather bags, belts, wallets, and accessories, ensuring exceptional quality, punctual delivery, and strict budget adherence.

Supporting Your Leather Goods Journey

Why Leading Brands Choose Hoplok

We go beyond standard manufacturing to become a true partner in your brand’s growth. Discover the core advantages that make Hoplok the trusted choice for quality, speed, and innovation.

01

Leverage our New York & California-based design team to stay ahead of market trends. We manage everything from concept and 3D modeling to global logistics, providing you with a seamless, end-to-end manufacturing solution.

02

Global Manufacturing Footprint

With strategically located factories in both China and Cambodia, we offer unmatched production flexibility. This dual-country advantage allows you to mitigate risks, optimize costs, and ensure a resilient supply chain for your brand.

03

In-House Leather Tannery

Our self-owned leather finishing facility gives us direct control over the entire production process. This vertical integration guarantees superior material quality, consistent finishes, and significant cost advantages from the source.

04

Proven by Top Brands

We are the trusted manufacturing partner for some of the world’s most recognized brands, including Calvin Klein, Macy’s, and J.Crew. Our standards are rigorously tested and proven at the highest level of the industry.

05

Uncompromising Quality

Quality is non-negotiable. Our facilities are fully certified with BSCI, SMETA, ISO 9001, and LWG standards, ensuring every product we create meets the strictest international requirements for quality, safety, and ethics.

06

Flexible & Fast

We support your growth with flexible MOQs. Our powerful, dedicated sample room produces over 1,500+ prototypes monthly, enabling you to test markets and bring your vision to life with industry-leading speed.

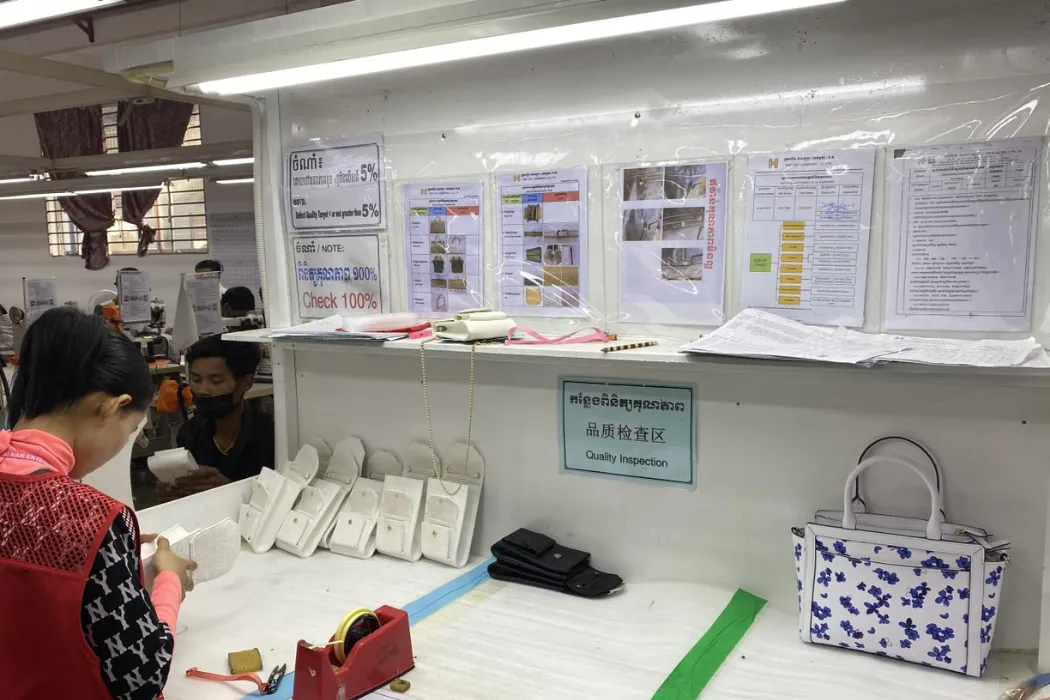

Our Fabric Expertise And Workshop Facilities

Vertical Integration: Our In-House Tannery

Our self-owned ProPelli facility provides complete control over the supply chain, ensuring superior quality and stability for your projects.

- Global Material Sourcing: Access premium hides from LWG-certified tanneries across Italy, Brazil, and beyond to perfectly match your quality and price-point targets.

- Unmatched Versatility: From classic cowhide and suede to sustainable vegan alternatives, we handle any material your design demands.

- Custom Finish Mastery: Realize your unique aesthetic with our expertise in finishes like oil-tanned, crazy horse, vintage-washed, and bespoke brand-specific effects.

- Reliable Daily Output: With a capacity of 20,000-50,000 sq. ft. daily, we ensure a stable supply of finished leather for even the largest production runs.

Powering Your Brand: Our Production Strength

Our three factories, powered by 4,500 skilled artisans, are built for the scale, speed, and excellence your brand deserves.

- Massive Monthly Capacity: Confidently meet global demand with our proven output of over 1 Million belts and 850,000+ bags each month.

- Speed-to-Market Workflow: Launch faster with our end-to-end process, taking your concept from design to full production in as little as 15-20 days.

- Certified Quality Assurance: Rest easy knowing our ISO, SMETA & BSCI certified processes and third-party checks keep defect rates consistently below 1%.

- Responsible & Sustainable Practices: Partner with a manufacturer committed to sustainability, utilizing certified leathers, eco-focused methods, and energy-efficient equipment.

Feedbacks From Our Customers

Frequently Asked Questions

What is the minimum order quantity for custom leather goods?

We set flexible MOQ at 100 units for production, with samples from 1 unit. This setup works for startups testing shoulder bags or wholesalers scaling men’s leather belts, reducing stock risks. Discounts apply to larger runs, and we adjust based on your market like affordable options for USA.

How long does it take to get a sample of leather products?

Samples reach you in 2-7 days after design sign-off. Our team sources materials like Italian full-grain leather or vegan alternatives, then crafts prototypes in our China or Cambodia sites. This quick turnaround aids fast decisions for items such as tote bags or braided belts.

Are samples free for leather goods orders?

We charge a modest fee for samples to handle materials, but credit it back on orders over 500 units. For custom wallets or duffle bags, this covers details like embossed logos or Pantone matches, giving you a hands-on check without major costs upfront.

What materials are used in leather bags and belts?

Options include full-grain cow leather for strength, PU for budget needs, suede for feel, and vegan leather for green choices. Sourced from tanneries in Argentina, Brazil, and Italy, with finishes like crazy horse. Hardware from China boosts durability in crossbody bags or women’s leather belts.

Can I customize logos on leather products?

Yes, we provide embossing, metal plates, printing, or embroidery to match your brand. Our U.S. designers create sketches and renders, fitting your style for leather goods. This helps create standout products that drive sales in retail.

What certifications ensure leather product quality?

We hold ISO 9001 for processes, SMETA and BSCI for ethics, OEKO-TEX for safety, and LWG for tanning. Third-party checks at every stage confirm standards for markets like REACH in Europe or CPSIA in USA, covering sling bags to genuine leather belts.

How do manufacturers maintain quality in leather goods?

Quality begins with material inspections, then stitching and assembly tests in our 50,000 square meter plants. We run durability checks for wear over years on men’s leather belts or cosmetic bags, using labs to meet your specs without shortcuts.

What is the production lead time for bulk leather orders?

Bulk runs finish in 45-90 days, ahead of many suppliers with our 4500 workers and capacity up to 800,000 belts monthly. We cover sourcing to shipping, with updates for custom laptop bags or PU leather belts to keep your timeline on track.

Expert Insights & Manufacturing Intelligence

Gain a competitive edge with deep dives into global leather sourcing, sustainable manufacturing protocols, and seasonal design forecasts. From navigating dual-country production advantages (China & Cambodia) to understanding the latest material compliances (LWG, REACH), our blog delivers the technical clarity and strategic foresight brand owners need to scale efficiently.

Ready to Build Your Leather Line?

Begin your journey with Hoplok Leather now. We can assist in wholesale or custom leather goods at the most competitive prices to enhance your brand.