Your Premier Custom Leather Belt Manufacturer

With strategic manufacturing in Cambodia and China, we offer a resilient supply chain and a capacity of over 1.5 million units monthly. We provide end-to-end solutions for the world’s leading brands, turning your vision into reality.

Trusted By:

Manufacturing Expertise Across All Core Belt Categories

We craft a diverse range of custom leather belts, tailored to the specific needs of your brand and market. Below is a showcase of our core production capabilities.

Our capabilities extend to a wide variety of specialized styles. Whether your brand requires western belts, studded belts, reversible belts, engraved logo belts, suspender belts, non-buckle or corset styles, our versatile production lines and skilled artisans can meet your specific design requirements.

We produce a full range of men’s belts, from classic full-grain leather styles for formal wear to rugged options for casual brands. Focus on durability and timeless design.

From wide waist-cinching belts to slim, elegant designs, we manufacture fashion-forward belts that complement any women’s apparel collection.

Precision-crafted for formal and business attire. We focus on clean lines, premium leathers, and high-quality polished hardware to reflect a sophisticated aesthetic.

Built for everyday style and durability. We work with a variety of leathers and hardware to create versatile belts perfect for denim, chinos, and casual wear brands.

Showcasing intricate craftsmanship, our braided and woven belts are perfect for resort, summer, and artisanal collections, available in both leather and multi-material designs.

Meeting the demand for sustainable and cost-effective options, we offer high-quality manufacturing for PU and vegan leather belts without compromising on style or finish.

We manufacture durable, safe, and playful belts for children’s apparel brands, using high-quality materials that meet international safety standards.

From classic leather suspenders for formal occasions to modern, fashion-forward designs, we produce high-quality suspenders with premium hardware and construction.

Bringing Your Unique Vision to Life: A Universe of Customization

Every detail of your belt can be fully customized. Explore the tabs below to see the wide range of options we offer to create a product that is truly unique to your brand.

-

Leather and Materials

-

Textures and Finishes

-

Hardware and Construction

-

Logo and Branding

-

Free Color Choice

Leather and Materials for Making Belts

The foundation of any great belt is the material. We source premium leathers from LWG-certified tanneries globally. Critically, our in-house leather finishing facility, ProPelli, gives us direct control over the final texture, color, and quality, ensuring we can perfectly match the aesthetic and durability your brand requires. This vertical integration allows us to offer unique, custom finishes that others can’t.

Below are some of our most requested materials. Our expert sourcing team and in-house facility can also develop unique and specialized leathers to meet any creative challenge. Let us know your requirements, and we will create the perfect material for your collection.

The highest quality hide, prized for its natural grain and exceptional durability. It develops a beautiful patina over time, perfect for premium and heritage brands.

The second-highest grade, with a sanded surface for a more uniform appearance. It offers excellent durability and a high-end finish, ideal for luxury goods.

A cost-effective real leather option made from the subsequent layers of the hide. Versatile and widely used for a variety of commercial belt styles.

Known for its soft, napped finish, suede offers a unique texture and a more casual, sophisticated look. Ideal for fashion-forward and footwear-matching collections.

High-quality synthetic alternatives offering consistency, a vast range of colors, and the ability to meet demands for sustainable and animal-free products.

Achieve the luxurious, exotic look of crocodile skin with high-quality embossing on genuine cowhide. This offers a premium aesthetic at a more accessible price point.

Replicate the distinctive “quill” pattern of ostrich leather on durable cowhide. This technique provides a unique, high-fashion texture for standout designs.

Often used for unique inlays or as a distinct feature, horsehair provides a rugged, textured look that is perfect for western-style or artisanal belt designs.

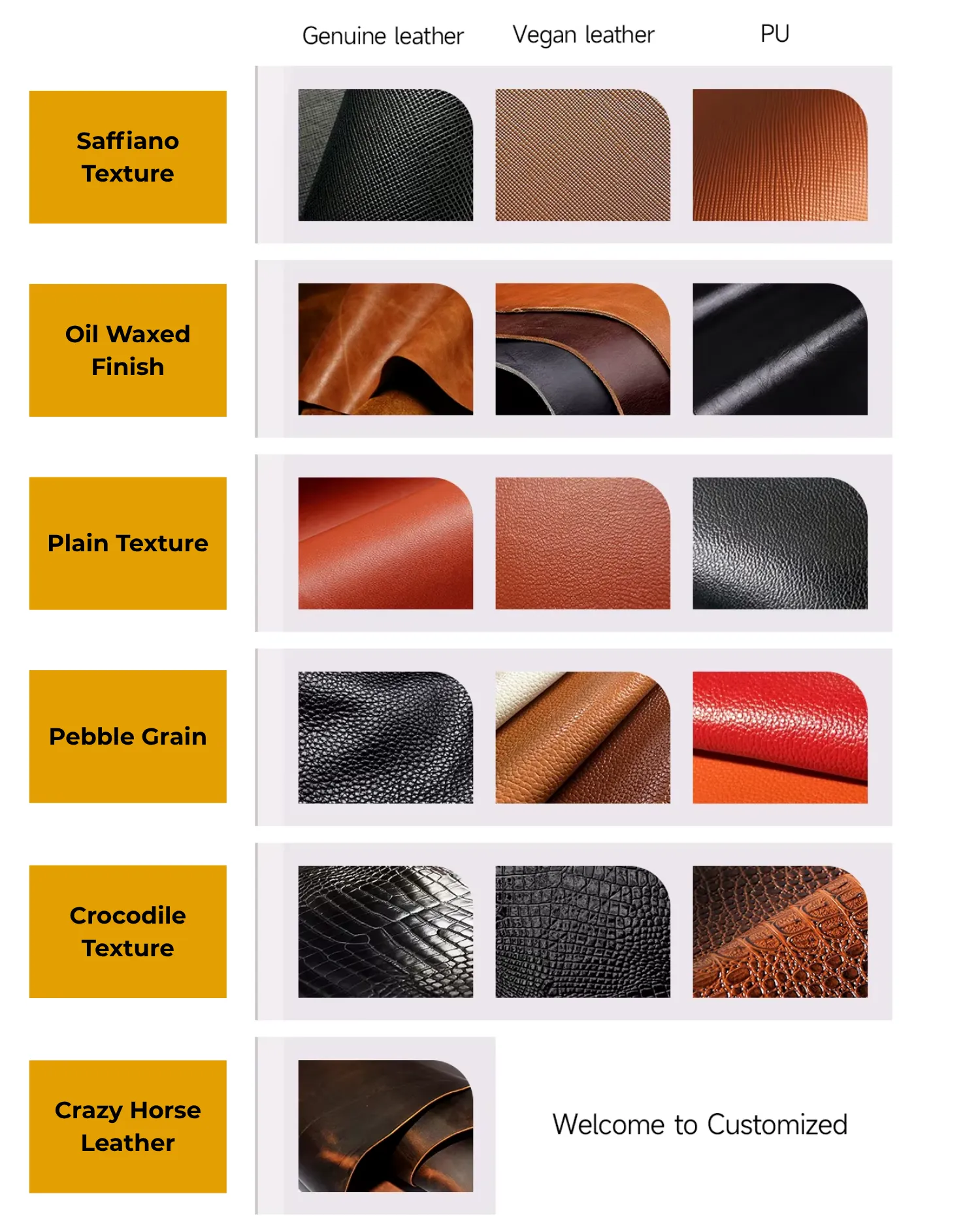

Leather Textures and Finishes For Making Belt

Beyond the type of leather, the texture and finish define the final character of your belt. Thanks to our in-house finishing facility, we have mastered a wide range of surface treatments to create unique visual and tactile experiences.

We can precisely control the grain, sheen, and feel of the leather to match your exact specifications. Whether you’re aiming for a rugged, vintage look or a sleek, modern aesthetic, our technical expertise ensures a flawless and consistent finish across your entire production run.

- Plain Texture: A classic, smooth finish for a clean and timeless look.

- Pebble Grain: A sophisticated, textured finish that is both durable and scratch-resistant.

- Saffiano Texture: A popular cross-hatch pattern, known for its elegance and resistance to wear.

- Crocodile Texture: High-quality embossing that replicates the bold, luxurious pattern of crocodile skin.

- Oil Waxed Finish: A treatment that gives the leather a rich, deep color and a rugged, pull-up effect.

- Crazy Horse Leather: A unique waxed finish that creates beautiful color variations as the belt is worn.

Buckles and Hardware for Making Belts

The buckle is the centerpiece of any belt, defining its character and style. We manufacture an extensive range of buckle types, from timeless classics to modern innovations, ensuring the perfect match for your design. Our hardware is sourced for its quality, durability, and premium feel in a wide range of metals and finishes.

For brands seeking true exclusivity, we offer custom hardware development. Our team can work with your designs to create a unique, proprietary buckle mold. This ensures your product is truly one-of-a-kind and stands out in the market.

The quintessential belt buckle, featuring a frame and pin. This timeless design is the standard for classic dress and casual belts. We offer countless shapes, including roller styles for reduced wear on the strap.

A solid plate, often detachable, that hooks into the strap. This design is a perfect canvas for bold logos, intricate engravings, or statement branding, ideal for fashion and western-style belts.

The modern solution for a clean look and precise fit. These track-based systems offer micro-adjustments without holes, perfect for performance, travel, or minimalist brands.

A sleek, no-holes design where the strap passes through a box and is held by friction or a simple locking mechanism. Popular for webbing, military, and minimalist belt styles.

A casual and often utilitarian style using one or two rings for a simple, secure closure. Commonly used with fabric, canvas, or woven leather for a relaxed aesthetic.

Designed for functionality and ease of use, these buckles, often seen on tactical or utility belts, provide a secure and quick-release mechanism.

A versatile twist or swivel mechanism that allows the belt to be worn on two different colored sides. This smart design offers double the value and styling options, a highly marketable feature.

Your unique design, brought to life. We specialize in creating exclusive molds for your brand’s signature logo, a completely original shape, or innovative mechanisms like magnetic closures.

Logo and Branding for Making Belts

Your brand’s logo is its signature. We offer a comprehensive suite of branding techniques to ensure your identity is represented with clarity, quality, and style. From subtle impressions on the leather itself to distinctive hardware and packaging elements, we help you make a lasting mark.

Our experienced technicians master both traditional craftsmanship and modern technologies to execute your branding with precision. We can advise on the best technique to match your chosen material and overall aesthetic, ensuring a professional and cohesive brand presentation across your entire product line.

The classic technique of pressing your logo into the leather to create a raised, 3D effect. This method adds a tangible, high-end feel perfect for sophisticated branding.

The inverse of embossing, this technique creates a sunken impression of your logo in the leather. It offers a subtle, elegant, and timeless branding statement.

A technique using high-quality thread to stitch your logo directly onto the belt. It adds rich texture and vibrant color, ideal for fabric, suede, or artisanal-style belts.

Elevate your brand with a custom metal logo plate, stud, or emblem affixed to the belt. This is an excellent way to showcase your brand with a premium, jewelry-like finish.

A modern, high-precision method that etches your design onto the leather surface. This is perfect for achieving sharp, clean lines and intricate details that other methods cannot.

The crucial final touch for retail presentation. We produce custom-branded hang tags in various materials and shapes to convey your brand story and product information at the point of sale.

A classic apparel branding method. A custom-woven fabric label featuring your brand name or logo is securely stitched onto the belt, typically on the inner side, for a professional, finished look.

Ideal for multi-color or complex graphic logos. We use durable, high-quality screen or digital printing to apply your design directly onto the material, offering limitless creative possibilities.

Integrate your brand directly into the belt’s hardware. We can customize snap buttons or rivets with your engraved or embossed logo, providing a subtle yet powerful branding detail.

Pantone Color Choices for Custom Leather Belts

Color is critical to brand identity. We offer a complimentary Pantone Color Matching service to ensure your belts perfectly align with your brand’s color palette and seasonal collections. Our color experts can achieve virtually any shade with precision and consistency.

Simply provide us with your Pantone color codes, and our team will manage the dyeing and finishing process to deliver an exact match on your chosen material. This service gives you complete creative freedom and guarantees brand cohesion across your entire product line, from the leather strap to the painted edges.

From Concept to Collection: Our Proven 6-Step Process

We believe in partnership and transparency. Our streamlined 6-step process ensures your project is managed with precision from concept to delivery, keeping you in control at every stage.

01

Design & Consultation

It all starts with your vision. Share your designs, tech packs, or ideas with our expert consultants. We’ll provide technical feedback to ensure your concept is perfectly production-ready.

02

Material Sourcing

Leveraging our global network and in-house tannery, we source the perfect materials to match your quality, price, and aesthetic requirements, providing swatches for your approval.

03

Prototyping & Approval

Our dedicated sample room creates a pre-production prototype in just 2-7 days, allowing you to test the design and materials before committing to bulk production.

04

High-Volume Production

Once the sample is approved, our state-of-the-art factories in Cambodia and China begin mass production, ensuring consistent quality and adherence to deadlines.

05

Quality Control & Inspection

Our dedicated QC team conducts rigorous multi-stage inspections. We also welcome third-party inspections to guarantee every piece meets your brand’s high standards.

06

Packaging & Global Delivery

The final step. We handle custom packaging, labeling, and all shipping logistics to deliver your products safely and on time to your warehouse, anywhere in the world.

The Art of Belt Making: Our Craftsmanship Process

Making a high-quality leather belt requires more than just good materials; it demands precision and expertise at every step. We combine traditional techniques with modern technology to ensure every belt we produce is perfectly crafted, durable, and reflects your brand’s commitment to excellence.

Here’s a glimpse into the key stages of our detailed belt-making process:

Why Choose Hoplok for Leather Belts Manufacturing?

When it comes to belt manufacturing, our capabilities provide a significant competitive edge for your brand. We combine scale, quality, vertical integration, and speed to deliver unparalleled value.

- Massive, Reliable Capacity

Confidently scale your business and meet global demand. Our specialized production lines are optimized for belts, enabling a massive monthly output of over 1.5 million units without sacrificing quality.

- Uncompromising Quality

Partner with a manufacturer trusted by the world’s top brands. Our processes are fully certified (LWG, ISO, SMETA, BSCI), and our multi-stage QC inspections ensure every belt meets the strictest international standards.

- In-House Tannery Advantage

Gain a unique edge with our in-house leather finishing facility, ProPelli. This gives us direct control over material quality, custom finishes, and lead times, offering stability and creative possibilities that others cannot match.

- Speed-to-Market

Launch your collections faster. Our streamlined workflow, from rapid 2-7 day prototyping to 15-20 day bulk production, allows you to react quickly to market trends and capture sales opportunities ahead of the competition.

Data-Driven Quality: Our Commitment to Excellence

For us, quality is not a slogan—it’s a science. We implement a rigorous, multi-stage quality control process, complemented by a suite of in-house physical testing capabilities. This ensures every belt we produce not only looks perfect but also performs to the highest standards of durability and safety.

Raw Material Inspection: All incoming leathers and hardware are meticulously inspected for flaws, color consistency, and compliance with your specifications.

In-Process Inspection: Our QC teams monitor every stage of production, from cutting and stitching to edge painting and assembly, to correct any deviations in real-time.

Final Product Inspection: Before packing, each finished belt undergoes a comprehensive final inspection to check for aesthetic perfection, structural integrity, and correct labeling.

Third-Party Audits: We welcome and regularly pass audits from clients and independent third-party agencies like SGS, Intertek, and Bureau Veritas.

High & Low Temperature Test: To ensure product stability in various climates.

Scratch Resistance Test: To verify the durability and quality of the leather finish.

Hydrolysis Test: To assess the material’s resistance to humidity and aging.

Tensile Strength Test: To guarantee the strength of the leather strap and buckle adhesion.

Wear Resistance Test: To simulate long-term use and test for abrasion.

Color Fastness Test: To ensure colors won’t rub off or fade under friction.

Frequently Asked Questions

For durability and a premium feel, Full-Grain Leather is the top choice. For a balance of quality and value, Top-Grain Leather is an excellent alternative. We can advise on the best option based on your design and target price.

Belt leather thickness typically ranges from 8 to 10 ounces (approx. 3.2mm to 4.0mm). A 9-ounce leather is a versatile standard for high-quality, durable belts. We can customize the weight based on your desired flexibility and style.

Look for solid construction, clean edge finishing, and high-quality hardware. A key indicator is the leather itself: Full-Grain leather will have natural, unique markings, unlike cheaper “Genuine Leather” which is often heavily processed.

We offer flexible MOQs to support brands of all sizes, typically starting at 100 units per style/color. We encourage you to contact us to discuss your project’s specific needs.

Yes, absolutely! We are more than just a factory; we are your design partner. We have a very talented design team based in the fashion centers of New York and California. They know all the latest market trends. If you only have a basic idea, they can help you develop it into a full, production-ready design. They can create sketches and 3D images to help you see your vision before we even make the first sample.

Ready to Produce Your Next Belt Collection?

Let’s discuss your project. Contact our belt manufacturing experts today for a free consultation and quote.