Sourcing leather bags in the USA is a strategic investment for brands targeting the luxury segment, despite domestic labor costs often exceeding $20 per hour. This guide curates the top 15 manufacturers, ranging from heritage workshops in Detroit to scalable hybrid solutions, helping procurement managers navigate a market projected to reach $420 billion globally by 2025. Whether you need strict “Made in USA” compliance or a partner offering American design with global cost efficiency, this list validates the best options available.

The resurgence of American manufacturing is driven by a consumer shift toward quality and transparency. Products carrying the “Made in USA” label can command retail premiums of 20% to 30% compared to imported alternatives. However, the challenge lies in scalability; with domestic tanning capacity shrinking by over 40% in the last two decades, finding a facility that can handle orders exceeding 1,000 units without compromising lead times is increasingly difficult. Brands must weigh the marketing value of domestic production against the realities of margin compression.

This 2025 sourcing guide is engineered for brand owners, boutique buyers, and enterprise supply chain managers. We have analyzed 15 top-tier facilities based on MOQ flexibility, ethical certifications (such as SMETA and ISO), and R&D capabilities. From small-batch artisans requiring MOQs as low as 50 units to industrial partners capable of producing 50,000+ units monthly, the following insights will help you secure a supply chain that balances craftsmanship with commercial viability.

The State of Leather Manufacturing in the USA

The US leather manufacturing landscape has shifted from mass production to specialized, high-value craftsmanship, currently accounting for less than 4% of global leather goods output. While Asian hubs dominate volume, American factories focus on heritage preservation, heavy-duty bridle leathers, and bespoke luxury markets where higher unit costs—often ranging from $100 to $500 per unit FOB—are offset by superior brand equity and reduced logistics carbon footprints.

Key Industry Trends for 2025

- Reshoring for Agility: Brands are moving 10-15% of production domestically to shorten lead times from 6 months to 4-6 weeks.

- Hybrid Sourcing Models: Smart brands utilize US design teams for prototyping while leveraging offshore partners like Hoplokleather for scalable production to average down costs.

- Sustainable Tanning: A push for vegetable-tanned leathers that comply with strict EPA regulations, despite being 30% more expensive than chrome-tanned alternatives.

6 Criteria Defining a Top-Tier Manufacturer

A top-tier leather manufacturer is defined by their ability to maintain sub-1% defect rates while adhering to international compliance standards like ISO 9001 and SA8000. Beyond basic sewing capabilities, elite factories distinguish themselves through vertical supply chain integration, ensuring material traceability from the tannery to the final stitch, and financial stability to handle net-30 or net-60 payment terms for established B2B clients.

1. Material Traceability & Tannery Relations

Top manufacturers do not rely on open-market stock lots. They maintain direct partnerships with LWG (Leather Working Group) Gold/Silver rated tanneries. This ensures that the Full-Grain leather used is free from excessive scarring and has been processed using sustainable methods. Verifiable traceability reduces the risk of chemical non-compliance (like REACH in Europe or Prop 65 in California) by over 95%.

2. Craftsmanship Consistency (SPI & Edge Paint)

Precision is measurable. High-end leather goods typically require a stitch density of 10-12 Stitches Per Inch (SPI) for aesthetic refinement and structural integrity. Furthermore, verify their edge finishing process; luxury standards demand at least 3 layers of hand-applied edge paint or artisanal burnishing, which prevents peeling even after 5+ years of daily use.

3. MOQ Flexibility (Minimum Order Quantity)

Scalability determines partnership longevity. An ideal manufacturer supports emerging lines with MOQs as low as 50-100 pieces per SKU while retaining the industrial capacity to ramp up to 5,000+ units as the brand grows. Rigid high MOQs (e.g., 1000+) often stifle design experimentation, leading to inventory risks averaging 20% of capital.

4. Ethical Labor Practices & Certification

In 2025, transparency is non-negotiable. Manufacturers must provide valid third-party audits such as SMETA (Sedex Members Ethical Trade Audit) or BSCI. These certifications guarantee fair wages and safe working conditions. Brands associated with non-compliant factories risk severe reputational damage and can face import bans under regulations like the UFLPA.

5. R&D and Fast Prototyping

Speed to market is a competitive advantage. Leading factories employ in-house sample masters capable of converting sketches to 3D CAD models within 24 hours and physical samples within 5-7 days. This rapid iteration cycle allows brands to launch seasonal collections 2-3 weeks ahead of competitors.

6. Supply Chain Resilience

The ability to mitigate disruption is critical. Top manufacturers maintain a safety stock of core hardware (zippers, rivets) and raw hides equivalent to 2 months of production. They also operate dual-sourcing strategies for critical components to prevent bottlenecks, ensuring an on-time delivery rate (OTD) exceeding 98%.

Understanding Leather Grades & Types

Leather grade is the single largest cost driver, accounting for 40% to 60% of the total FOB price. Understanding the distinction between Full-Grain (the entire hide surface) and Bonded Leather (reconstituted scraps) is essential for accurate pricing and durability expectations; a Full-Grain bag can last decades, while Bonded leather may degrade within 6 months.

| Leather Type | Durability Score (1-10) | Cost Index | Best Application |

|---|---|---|---|

| Full-Grain Leather | 10/10 | $$$$$ | Luxury Heritage Bags, Belts |

| Top-Grain Leather | 8/10 | $$$$ | High-End Fashion Handbags |

| Genuine Leather (Split) | 5/10 | $$ | Mid-Tier Fashion, linings |

| Bonded Leather | 2/10 | $ | Low-Cost Accessories, padding |

Quick Comparison: Top 15 Manufacturers

This comparison matrix provides a snapshot of the top 15 manufacturers serving the US market, categorized by their primary operational strengths and minimum order thresholds.

| Manufacturer Name | Location | MOQ | Best For |

|---|---|---|---|

| Shinola | Detroit, MI | High | Luxury Assembly & Watches |

| Filson | Seattle, WA | High | Rugged Outdoor Gear |

| Frank Clegg | Fall River, MA | Low | Bespoke Executive Goods |

| Lotuff Leather | Providence, RI | Low | Lifetime Guarantee Goods |

| Ghurka | Norwalk, CT | Medium | Military-Inspired Luxury |

| Saddleback Leather | Fort Worth, TX | Medium | Heavy-Duty Travel Bags |

| J.W. Hulme Co. | St. Paul, MN | Medium | Heritage Americana Style |

| Hoplokleather | US Design / Asia Mfg | Flexible (Low) | Scalable OEM & Duty-Free |

| Colonel Littleton | Lynnville, TN | Low | Nostalgic/Vintage Leather |

| Go Forth Goods | Marietta, GA | Low | Minimalist Daily Carry |

| Rough & Tumble | Brunswick, ME | Low | Designer Soft Leather Bags |

| Billykirk | Jersey City, NJ | Low | Amish Craftsmanship |

| Schott NYC | Union, NJ | Medium | Motorcycle/Heritage Style |

| Mission Workshop | San Francisco, CA | Medium | Technical/Urban Gear |

| Coronado Leather | San Diego, CA | Medium | Concealed Carry (CCW) |

Top 15 Leather Bag Manufacturers in The USA

The following list represents the pinnacle of American leather craftsmanship. We have categorized these manufacturers by their specific operational strengths, ranging from high-volume industrial facilities to small-batch heritage workshops. Each entry includes verified data points on capacity and specialization to assist your procurement decision.

1. Shinola

Year Established: 2011

Location: Detroit, MI

MOQ: High (500+ for custom B2B)

Production Lead Time: 8-12 weeks

As a symbol of American industrial revitalization, Shinola operates a state-of-the-art leather factory dedicated to producing luxury timepieces and leather goods. They specialize in high-end assembly, sourcing premium hides from US tanneries to create products that define modern American luxury for corporate and retail markets.

What Sets Shinola Apart:

- Operates a massive manufacturing hub in Detroit focused on job creation.

- Specializes in corporate gifting and large-scale B2B partnerships with luxury branding.

- Uses premium American hides tanned in heritage facilities like Horween Leather.

- Maintains rigorous quality control standards originally developed for precision watch assembly.

- Offers sophisticated debossing and customization services for high-volume enterprise clients.

2. Filson

Year Established: 1897

Location: Seattle, WA

MOQ: High (Wholesale Partner Program)

Production Lead Time: 3-6 months

Renowned for equipping gold rush prospectors, Filson stands as the gold standard for rugged, heavy-duty leather and canvas goods. Their manufacturing philosophy prioritizes extreme durability, utilizing heavyweight bridle leathers and tin cloth to produce bags guaranteed to withstand the harshest outdoor environments.

What Sets Filson Apart:

- Famous for an unfailing lifetime guarantee against material and workmanship defects.

- Utilizes saddle-grade bridle leather that requires minimal maintenance over decades of use.

- Operates two dedicated factories in the Pacific Northwest for specialized manufacturing.

- Combines industrial sewing capacity with traditional hand-finishing techniques for maximum strength.

- Best suited for brands targeting the premium outdoor and heritage workwear markets.

3. Frank Clegg

Year Established: 1970

Location: Fall River, MA

MOQ: Low (Bespoke Available)

Production Lead Time: 4-8 weeks

Recognized globally for making President Obama’s briefcase, Frank Clegg represents the pinnacle of family-owned artisanal excellence. They focus on vegetable-tanned leather goods, offering bespoke services where every edge is hand-burnished and every hide is personally selected to ensure flawless grain consistency.

What Sets Frank Clegg Apart:

- Uses exclusively vegetable-tanned leathers that develop a rich, unique patina over time.

- Every product is designed and crafted in-house by a skilled family team.

- Offers “Made to Order” services allowing for high levels of individual customization.

- Known for signature hardware design and custom-developed solid brass fittings and locks.

- Ideal for luxury boutique brands seeking limited-edition runs with artisanal provenance.

4. Lotuff Leather

Year Established: 2013

Location: Providence, RI

MOQ: Low (Small Batch)

Production Lead Time: 4-6 weeks

Operating out of a dedicated studio in Providence, Lotuff Leather is celebrated for its unconditional lifetime guarantee and minimalist aesthetic. Their team of artists and craftspeople employs traditional techniques to create full-grain leather bags that blend modern functionality with timeless structural integrity.

What Sets Lotuff Leather Apart:

- Provides an unconditional guarantee covering every stitch and lock for life.

- Hand-selects only 10% of vegetable-tanned hides to ensure zero surface imperfections.

- Specializes in fully leather-lined bags which increase durability and luxury feel.

- Maintains a transparent studio environment where clients can witness the production process.

- Perfect for high-end fashion labels requiring superior craftsmanship and ethical production.

5. Ghurka

Year Established: 1975

Location: Norwalk, CT

MOQ: Medium (Corporate Sales)

Production Lead Time: 8-10 weeks

Inspired by the British Gurkha soldiers, Ghurka is famous for its military-grade aesthetics and signature chestnut leather. While they have diversified production, their core identity remains rooted in producing distinct, ruggedly elegant luggage and accessories that appeal to the adventurous luxury traveler.

What Sets Ghurka Apart:

- Signature “Chestnut” leather tanning process creates a distinct and recognizable brand identity.

- Known for rigorous product testing to meet military-inspired standards of durability.

- Features solid brass hardware and signature check linings in all heritage pieces.

- Offers a robust corporate gifting program with custom embossing and packaging options.

- Ideal partnership for brands looking to convey a sense of history and adventure.

6. Saddleback Leather

Year Established: 2003

Location: Fort Worth, TX

MOQ: Medium (Wholesale Inquiries)

Production Lead Time: 8-12 weeks

Famous for their slogan “They’ll Fight Over It When You’re Dead,” Saddleback Leather designs functional, over-engineered bags using thick full-grain boot leather. Their manufacturing philosophy rejects breakable parts like zippers and snaps, opting instead for heavy-duty hardware and reinforcement to back their legendary 100-year warranty.

What Sets Saddleback Leather Apart:

- Offers a transferable 100-year warranty that underscores extreme product durability.

- Constructs bags with no breakable parts like zippers, buttons, or snaps.

- Uses extra-thick full-grain leather that is significantly heavier than standard bags.

- Designs are tested internationally to ensure functionality in extreme travel conditions.

- Best for brands positioning themselves as the toughest option on the market.

7. J.W. Hulme Co.

Year Established: 1905

Location: St. Paul, MN

MOQ: Medium (Corporate/Wholesale)

Production Lead Time: 6-10 weeks

With over a century of history, J.W. Hulme Co. is one of the oldest operating leather goods manufacturers in the USA. They specialize in classic American heritage styles, utilizing exclusive premium leathers tanned in the US to create timeless travel bags, briefcases, and accessories for the luxury market.

What Sets J.W. Hulme Co. Apart:

- Boasts over 100 years of continuous manufacturing history in the Midwest.

- Offers a unique “Guaranteed for Life” policy on all heritage leather products.

- Uses proprietary “American Heritage” leathers tanned exclusively for their product lines.

- Provides complimentary embossing and conditioning services to enhance customer lifetime value.

- Ideal for heritage brands seeking deep historical roots and classic aesthetics.

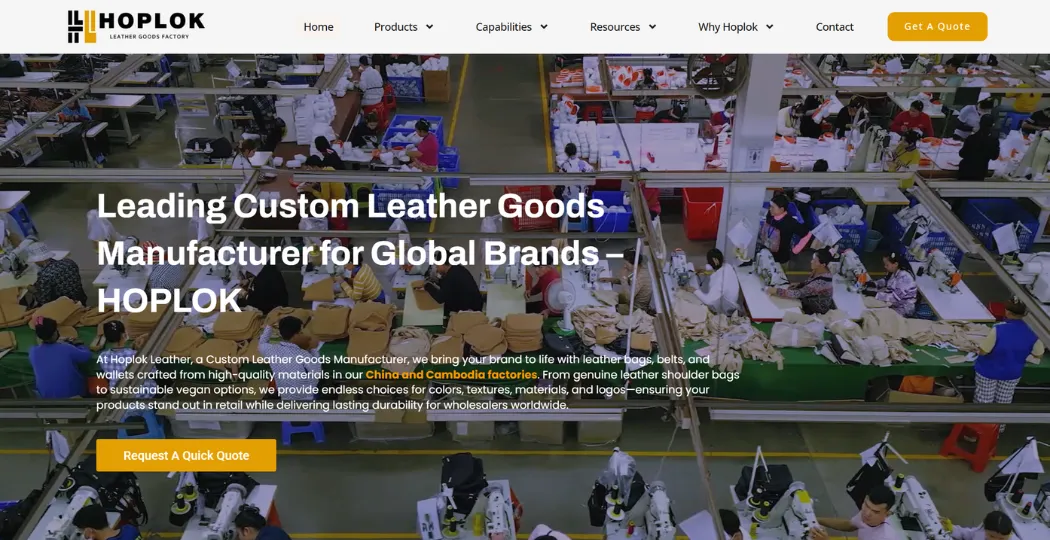

8. Hoplokleather

Year Established: 2002

Location: US Design / Asia Mfg

MOQ: Flexible (Low to High Volume)

Production Lead Time: 3-5 weeks

Serving as the strategic bridge between American design standards and global manufacturing efficiency, Hoplokleather offers a unique hybrid solution. By combining a US-based design team in New York with self-owned, duty-free factories in Cambodia, they provide scalable capacity and cost advantages that purely domestic manufacturers cannot match.

What Sets Hoplokleather Apart:

- Operates massive 30,000 sqm facilities across China and Cambodia for scalable production.

- Monthly output exceeds 800,000 belts and 60,000 leather bags for global retailers.

- Owns Pro Pelli tannery, processing 50,000 sq ft of custom leather daily.

- US-based design team ensures seamless communication and on-trend product development.

- Duty-free manufacturing in Cambodia offers significant landed cost savings for US buyers.

9. Colonel Littleton

Year Established: 1987

Location: Lynnville, TN

MOQ: Low (Niche Wholesale)

Production Lead Time: 4-8 weeks

Operating from a small town in Tennessee, Colonel Littleton is the purveyor of “The Great American Leather Company” aesthetic. They focus on nostalgic, Americana-inspired designs, often incorporating unique closures and antique hardware. Their packaging and storytelling are integral to the product, creating an emotional connection with the buyer.

What Sets Colonel Littleton Apart:

- Designs feature unique, patented closure mechanisms inspired by military history.

- Every product comes with distinct, nostalgic packaging that enhances unboxing experiences.

- Specializes in American Buffalo and Steerhide leathers with rich, vintage character.

- Maintains a strong focus on storytelling and personal connection in branding.

- Perfect for gift-oriented retailers looking for products with built-in emotional appeal.

10. Go Forth Goods

Year Established: 2014

Location: Marietta, GA

MOQ: Low (Small Batch Friendly)

Production Lead Time: 3-5 weeks

Founded on the principle of simplicity and longevity, Go Forth Goods produces handmade leather bags with a rugged, minimalist aesthetic. Their designs focus on functionality and reducing failure points, appealing to the “buy it for life” demographic. They offer a flexible approach suitable for smaller boutiques and custom runs.

What Sets Go Forth Goods Apart:

- Offers a straightforward lifetime guarantee on all handmade leather goods.

- Focuses on minimalist designs that reduce production costs and potential failure points.

- Sources all leather and materials exclusively from suppliers within the USA.

- Provides a highly personal manufacturing experience for small-batch custom orders.

- Ideal for lifestyle brands targeting the minimalist and sustainable consumer segments.

11. Rough & Tumble

Year Established: 2008

Location: Brunswick, ME

MOQ: Low (Boutique Friendly)

Production Lead Time: 4-6 weeks

Standing out for their “unstructured” luxury aesthetic, Rough & Tumble specializes in soft, convertible leather bags that prioritize functional versatility. Their Maine-based studio is famous for producing distinctive, slouchy silhouettes using premium Italian and domestic leathers, offering a relaxed alternative to rigid traditional designs.

What Sets Rough & Tumble Apart:

- Famous for the “1909” collection featuring unlined, ruggedly soft premium leathers.

- Offers unique “Design Your Own” services for high-end boutique customization options.

- Production is kept entirely in Maine to ensure artisanal quality control standards.

- Designs focus on functional versatility, often converting seamlessly from tote to backpack.

- Ideal for fashion-forward brands seeking a relaxed, bohemian luxury design aesthetic.

12. Billykirk

Year Established: 1999

Location: Jersey City, NJ

MOQ: Low (Wholesale Available)

Production Lead Time: 4-8 weeks

Founded by brothers Chris and Kirk Bray, Billykirk has been a driving force in the “Made in America” movement. They utilize traditional Amish leatherworking techniques to create durable, understated goods that emphasize utility and longevity, sourcing leather primarily from renowned US tanneries like Wickett & Craig.

What Sets Billykirk Apart:

- Utilizes Amish leather crafting techniques for exceptional durability and superior stitching strength.

- Sources high-quality vegetable-tanned leather from renowned US tanneries like Wickett & Craig.

- Known for understated, masculine designs that age beautifully with daily rigorous use.

- Offers a wide range of small leather goods alongside larger travel bags.

- Perfect for heritage menswear brands looking for authentic, handcrafted accessories partners.

13. Schott NYC

Year Established: 1913

Location: Union, NJ

MOQ: Medium (Distributor Focused)

Production Lead Time: 8-12 weeks

While legendary for creating the first motorcycle jacket, Schott NYC applies the same heavy-duty manufacturing standards to their leather bags. Their facility produces iconic, rugged items using thick steerhide and horsehide, designed to complement their heritage outerwear and appeal to the moto-lifestyle demographic.

What Sets Schott NYC Apart:

- Legendary status in American fashion history adds significant brand value and trust.

- Uses heavy steerhide and horsehide similar to their iconic motorcycle jacket lines.

- Manufacturing process emphasizes extreme durability and resistance to abrasion and heavy wear.

- Offers a distinctively rugged, rebellious aesthetic appealing primarily to motorcycle culture consumers.

- Ideal for streetwear or heritage brands seeking a tough, iconic manufacturing partner.

14. Mission Workshop

Year Established: 2009

Location: San Francisco, CA

MOQ: Medium (Technical Gear)

Production Lead Time: 6-10 weeks

Operating at the intersection of technical gear and luxury, Mission Workshop manufactures advanced carry systems in San Francisco. They are unique for blending high-performance fabrics with leather accents, creating weatherproof bags that cater to the urban cyclist and the modern technical professional.

What Sets Mission Workshop Apart:

- Pioneers in the “technical luxury” space, blending leather with high-performance fabrics.

- Bags feature weatherproof construction suitable for urban cycling and all-weather commuting.

- Utilizes advanced hardware systems like Arkiv® rails for modular user customization.

- Focuses on ergonomic design and functionality for the modern urban professional user.

- Best for tech-wear or active lifestyle brands requiring high-performance product specifications.

15. Coronado Leather

Year Established: 1981

Location: San Diego, CA

MOQ: Medium (Law Enforcement)

Production Lead Time: 8-10 weeks

Specializing in a niche but high-demand market, Coronado Leather is the premier manufacturer of concealment leather goods. They combine premium American bison and cowhide with specialized internal designs for law enforcement and civilians, setting the standard for quality in the tactical leather segment.

What Sets Coronado Leather Apart:

- The industry leader in premium leather concealment (CCW) handbags, vests, and jackets.

- Works closely with law enforcement agencies to ensure functional and safe designs.

- Uses premium American bison and cowhide for a distinct, rugged texture profile.

- Designs incorporate specialized locking zippers and holsters for secure, discreet carry.

- The go-to manufacturer for brands targeting the tactical or security consumer markets.

Domestic vs. Offshore: Which Model Fits Your Brand?

Choosing between domestic and offshore manufacturing is fundamentally a calculation of Brand Equity vs. Profit Margin. While “Made in USA” products can justify a 20-30% higher retail price point, the cost of goods sold (COGS) is typically 3x to 5x higher than offshore alternatives due to labor rates exceeding $20/hour domestically versus $2-4/hour in Asia.

For ultra-luxury brands selling handbags above $800, domestic manufacturing protects brand heritage. However, for scaling fashion brands targeting the $100-$400 mid-market range, a “Designed in USA, Made Globally” strategy is often the only path to sustainable profitability. This hybrid model allows brands to leverage American design innovation while capitalizing on the massive scalability and duty-free advantages offered by partners like Hoplokleather in Cambodia.

How to Verify a Manufacturer’s Credibility

Verifying a supplier’s credibility requires a multi-layered audit process that goes beyond scanning a website. A reliable manufacturer should proactively provide audited financial reports, valid third-party certifications (like BSCI or Sedex), and a transparent track record of on-time delivery rates exceeding 95% over the last 12 months.

1. Request Comprehensive Sample Reports

- Inspection Report Requirements: Do not just ask for a sample; require a full report including measurements and swatches.

- Stress Testing Data: Ensure the report contains load-bearing test results for handles and straps.

- Stitching Consistency: Verify if the stitching meets the requested 10-12 SPI standard consistently.

- Edge Finishing: Check if the edge paint has passed a cross-hatch adhesion test to prevent peeling.

2. Validate Third-Party Audits (ISO, Sedex, SMETA)

- Verify Reference Numbers: Ask for the factory’s unique audit ID and check it with the issuing body like SGS.

- SMETA 4-Pillar: A valid SMETA audit ensures adherence to ethical labor, safety, and environmental standards.

- License Expiry: Always check the expiration dates on ISO certificates to ensure they are current.

- Risk Mitigation: Valid audits protect your brand from supply chain scandals and compliance issues.

3. Conduct Virtual or Physical Factory Tours

- Live Video Walkthroughs: If physical travel isn’t possible, request a real-time video tour of the floor.

- Raw Material Storage: Ask to see the warehouse to verify stock levels and proper leather storage conditions.

- QC Line Action: Observe the quality control team in action to understand their inspection process.

- Facility Scale: Legitimate partners like Hoplok will transparently showcase their large-scale 30,000 sqm facilities.

4. Assess Communication Speed & Cultural Fit

- Response Time Testing: Send a complex query and measure the time to reply; expect within 24 hours.

- Technical Clarity: Evaluate if their answers demonstrate a deep understanding of technical manufacturing details.

- Design Team Alignment: Partners with a US-based design team can eliminate language barriers and timezone delays.

- Proactive Updates: A good partner provides regular status updates without being constantly chased.

5. Review Financial Stability

- Credit Checks: Run a credit check to ensure the factory has the liquidity to fulfill orders.

- Payment Terms: Stable partners usually accept standard terms like 30% deposit, 70% upon shipping.

- Bank References: Request bank references to verify their financial history and standing.

- Inventory Liquidity: Ensure they have the funds to purchase raw materials without 100% upfront payment.

6. Check Material Traceability

- Proof of Origin: Demand documentation proving the origin of the raw leather hides.

- LWG Certification: Trace hides back to LWG-certified tanneries in regions like Italy or Brazil.

- Regulatory Compliance: Traceability is crucial for complying with the Lacey Act and avoiding restricted substances.

- Supply Chain Transparency: A credible manufacturer will have full visibility into their material supply chain.

Sourcing Strategy Matrix: Domestic vs. Hybrid vs. Traditional

This decision matrix compares three common sourcing models to help you identify the best fit for your brand’s growth stage and budget.

| Factor | Domestic US Factory | Hoplok (Hybrid Model) | Standard Asian Factory |

|---|---|---|---|

| Cost Efficiency | Low ($$$$) | High ($$) – Duty Free | High ($) |

| Lead Time | Fast (4-8 Weeks) | Moderate (3-5 Weeks) | Slow (8-12 Weeks) |

| MOQ Flexibility | Low (Small Batch) | High (Flexible) | Rigid (High Volume) |

| Design Support | High (Direct Collab) | High (US Team) | Low (Language Barrier) |

| Supply Chain Risk | Low | Low (Dual-Shore) | Medium/High |

Why the Hybrid Model (Hoplok) Optimizes ROI

- Duty-Free Savings: Manufacturing in Cambodia allows for 0% import duties to major markets like the US and EU.

- Design Synergy: A US-based design team bridges the gap between Western trends and Eastern manufacturing efficiency.

- Scalable Capacity: The ability to scale from 50 units to 50,000 units supports rapid brand growth.

- Cost Averaging: Blending costs allows for a higher profit margin without sacrificing product quality.

Landed Cost Comparison Scenario (1,000 Units)

| Cost Element | Domestic US Mfg | China Mfg | Cambodia Mfg (Hoplok) |

|---|---|---|---|

| FOB Unit Price | $120.00 | $35.00 | $32.00 |

| Import Duty (US) | $0.00 | ~25% ($8.75) | 0% ($0.00) |

| Freight (Est.) | $2.00 | $5.00 | $5.00 |

| Total Landed Cost | $122.00 | $48.75 | $37.00 |

Typical Leather Bag Cost Breakdown

Understanding the cost structure of a premium leather bag helps in negotiation and pricing strategy. The following breakdown is typical for a high-quality leather tote manufactured by an efficient OEM partner.

| Cost Component | Estimated Percentage | Notes |

|---|---|---|

| Raw Materials (Leather) | 45% – 55% | Full-Grain accounts for the bulk of costs. |

| Hardware & Lining | 10% – 15% | Custom zippers (YKK) and solid brass fittings. |

| Labor & Craftsmanship | 20% – 25% | Cutting, skiving, stitching, and edge painting. |

| Factory Overhead | 10% | Utilities, machinery maintenance, and QC. |

| Manufacturer Profit | 10% – 15% | Standard industry margin for sustainable ops. |

Hidden “Soft Costs” Often Overlooked

- Sample Development: Prototyping fees can range from $100 to $500 per SKU before bulk production begins.

- Mold & Tooling Charges: Custom hardware or embossed logos often require one-time mold fees of $50-$200.

- Third-Party Inspection: Hiring agencies like SGS for final inspection adds roughly $300-$500 per man-day.

- Compliance Testing: Lab testing for lead, phthalates (Prop 65), or REACH compliance adds to the initial cost.

Strategies to Reduce FOB Costs

- Material Substitution: Switching from full-grain to top-grain leather can save 15-20% without major visual impact.

- Hardware Simplification: Using standard stock hardware instead of custom-molded pieces reduces tooling costs.

- Volume Leverage: Increasing order quantity from 100 to 500 units can often lower unit costs by 10-15%.

- Design Optimization: Simplifying patterns to improve leather yield (nesting) reduces material waste significantly.

Conclusion: Partnering for Profitability in 2025

Sourcing leather bags involves a critical trade-off: the marketing cachet of “Made in USA” versus the scalability of global manufacturing. While domestic partners offer heritage value, their unit costs often exceed $100, compressing margins for scaling brands. The most successful labels in 2025 are adopting a hybrid strategy—maintaining a small domestic footprint for PR while shifting bulk production to compliant, cost-efficient partners.

Hoplokleather stands uniquely positioned to bridge this gap. By combining a New York-based design team with self-owned, duty-free factories in Cambodia, Hoplok eliminates communication barriers and tariff costs without sacrificing quality. With full SMETA and BSCI compliance and a monthly capacity of 60,000+ leather bags, Hoplok offers the reliability of an American partner with the competitive pricing of an Asian manufacturer.

Ready to scale your leather goods brand?

Stop compromising between quality and cost. Contact Hoplokleather today for a free design consultation and receive a custom quote within 24 hours.