Have you ever experienced the frustration of a suspender strap constantly sliding off your shoulder during a busy day? Or perhaps you have felt the sharp dig of a metal joiner pressing into your spine while sitting in the driver’s seat. These aren’t just minor annoyances; they are symptoms of choosing the wrong back structure for your specific activity level.

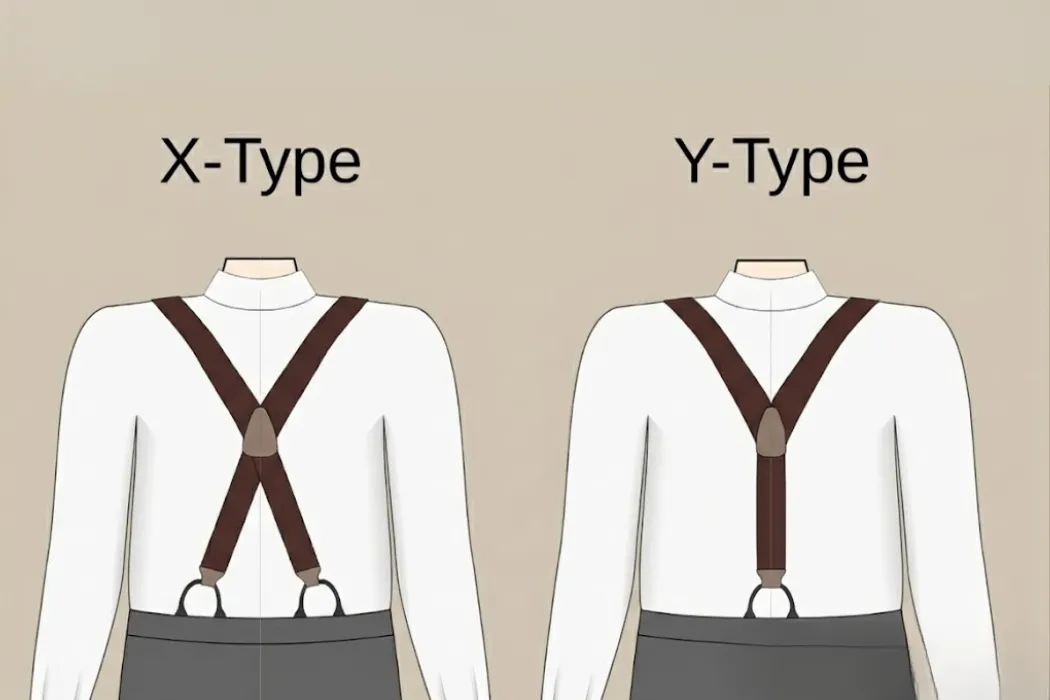

The choice between X-Back and Y-Back is not merely aesthetic. It is a fundamental physical trade-off between Maximum Stability (the 4-point anchor system) and Optimal Formality (the 3-point central pivot system). Choosing the wrong one compromises either your silhouette or your range of motion.

In this structural analysis, we will compare the mechanics of both designs, define which scenarios dictate their use, and explain how different body types react to these distinct load-bearing configurations.

What is the Mechanical Difference Between X-Back and Y-Back?

The distinction lies entirely in the anchor geometry. The X-back utilizes a 4-point anchor system designed for maximum lateral stability and load dispersion, whereas the Y-back employs a 3-point system that functions as a central pivot for refined movement. Think of it as the difference between a rugged 4-wheel drive vehicle and a precision 3-wheeled motorcycle.

The 4-Point Anchor System (X-Back)

The X-back is the industrial standard for a reason. By attaching to the rear waistband at two distinct points (typically spaced 4–6 inches apart), it creates a structural cage.

- Lateral Stability: Because the straps are anchored wide on the back, they prevent the trousers from sagging at the hips. This provides superior Lateral Stability, ensuring that heavy fabrics (like denim) or weighted pockets (tool belts) remain level across the entire waistline.

- Load Sharing: The tension is split between four distinct vectors. If you lean to the left, the right rear strap takes up the slack, maintaining constant support.

The Central Pivot System (Y-Back)

The Y-back simplifies the rear connection into a single strap that runs down the spine, creating a sophisticated “floating” effect.

- The Central Pivot: The single rear anchor point acts as a fulcrum. When your shoulders rotate or twist, the central strap pivots slightly. This allows for spinal micro-adjustments without aggressively pulling on the waistband, resulting in a cleaner drape that doesn’t bunch up.

- Vertical Linearity: Mechanically, a single vertical line creates less visual noise. This is why Y-backs are the standard for formalwear; they disappear under a jacket without creating the “double humps” on the back that X-backs often cause.

The Joinery Patch (Leather Integrity)

The point where the straps cross or merge is the structural heart of the suspender. This patch endures multi-directional stress.

- Stress Concentration: At Hoplok, we observe that the joinery patch is the #1 failure point on cheap suspenders. It must withstand tension from the shoulders pulling up and the pants pulling down, simultaneously.

- Full-Grain Requirement: We engineer our patches using Full-Grain Vegetable-Tanned Leather. Synthetic or bonded leather patches will delaminate and tear at the stitch holes under this bi-directional tension. The fiber density of real leather is non-negotiable here for longevity.

| Structural Metric | X-Back Suspenders | Y-Back Suspenders |

|---|---|---|

| Anchor Points | 4 Points (2 Front, 2 Rear) | 3 Points (2 Front, 1 Rear) |

| Load Distribution | Wide spread across hips | Centered on spine |

| Lateral Stability | High (Prevents side sag) | Medium (Allows more movement) |

| Range of Motion | Restricted (Secure) | Fluid (Pivoting) |

Which Style Offers Better Support for Active Use?

When mobility and load-bearing capacity are the priority, the X-back structure is mechanically superior due to its wider stance and redundant anchor points. While the Y-back excels in static formal settings, the X-back is engineered to handle dynamic torque and heavy loads without mechanical failure.

The “Clip-Slip” Phenomenon

One of the most common complaints we investigate at Hoplok is the rear clip popping off when a user bends over. This is a vector physics issue.

- Load Concentration (Y-Back): When you bend forward at the waist, your back length increases. On a Y-back, 100% of this tension is directed to a single rear anchor point. If you are using clips, this concentrated force often exceeds the clip’s grip strength (approx. 20 Newtons), causing it to snap off.

- Load Distribution (X-Back): On an X-back, that same tension is divided between two rear anchor points. Each clip bears only 50% of the load, significantly reducing the risk of accidental detachment during physical labor.

Shoulder Width Compatibility

The geometry of your upper body dictates which strap style will stay put.

- Broad Shoulders (X-Back): Men with wide, square shoulders often prefer X-backs because the straps are spaced wider apart (typically 8–10 inches at the yoke). This prevents the straps from chafing against the neck.

- Sloping Shoulders (Y-Back): For men with narrower or sloping shoulders, X-back straps tend to slide outward and off the deltoids. The Y-back converges at the center of the spine, creating an inward angle that naturally pulls the straps away from the shoulder edge, keeping them secure without constant adjustment.

Heavy Duty Loads (Tool Belts)

If you are supporting more than just trousers—such as a tool belt or heavy denim—structural redundancy is required.

- The 2kg Threshold: Once the total load on the waist exceeds 2kg (4.4 lbs), a Y-back can cause neck strain due to the central pivot point acting on the cervical spine.

- Industrial Standard: X-backs are the global standard for logging, construction, and firefighting suspenders. The four vertical lines transfer heavy loads squarely onto the strongest part of the trapezius muscles, minimizing fatigue.

How Does Formality Dictate the Back Shape?

Formality in menswear is defined by clean lines and the absence of bulk. Therefore, the Y-back is the mandatory standard for formal attire due to its streamlined profile, while the X-back is aesthetically reserved for rugged, utilitarian environments. Choosing the wrong shape for the occasion is a disruption of the intended silhouette.

The Tuxedo Standard (Y-Back Only)

Black Tie etiquette is unforgiving. The goal is to make the hardware invisible.

- The “Printing” Problem: Under a fine, high-thread-count (Super 120s+) dinner jacket, bulky hardware shows through. An X-back creates two distinct ridges or “humps” on the shoulder blades that can be seen through the fabric.

- Vertical Linearity: A Y-back converges into a single strap that sits in the natural valley of the spine. This creates a single vertical line that remains invisible under a jacket, maintaining the sleek, uninterrupted profile required for formal events.

Business Professional Standards

In the boardroom, tradition dictates the uniform. While less strict than Black Tie, business attire still favors the Y-back.

- The Button-On Norm: Professional surveys and style guides consistently rate the Button-On Y-Back as the default for business suits. It signals adherence to sartorial tradition.

- Visual Balance: A 1.5-inch Y-back strap complements the lapel width of a standard business suit. An X-back often looks too busy or “heavy” when the jacket is removed.

Workwear and Denim (X-Back Territory)

When the fabric gets heavier, the hardware must match the visual weight.

- Proportion Match: Heavy raw denim (14oz+) demands substantial support. The X-back, typically found in 2-inch (50mm) widths, matches the chunkiness of work boots and flannel shirts.

- The “Logger” Aesthetic: The wide stance of the X-back creates a broad, masculine silhouette that fits the heritage workwear look. A thin Y-back looks fragile and out of place against rugged canvas materials.

| Occasion | Recommended Style | The Engineering Reason |

|---|---|---|

| Tuxedo / Black Tie | Y-Back (Silk) | Eliminates visible ridges under thin jackets. |

| Business Suit | Y-Back (Elastic/Cloth) | Traditional standard; cleanest drape. |

| Office Casual (Chinos) | Y-Back or X-Back | Both acceptable; Y-back leans dressier. |

| Manual Labor / Construction | X-Back (2″ Width) | Maximum load distribution; 4-point security. |

Does Body Type Affect the Choice of Back Style?

Ergonomics is not a “one size fits all” discipline. Your somatic type—specifically the relationship between your shoulder width and waist circumference—should dictate your suspension architecture. Choosing a style that fights your natural geometry results in constant slippage and adjustment.

The “V-Taper” vs. “O-Shape” Torso

The distribution of body mass changes the center of gravity for the trousers, requiring different anchor strategies.

- The V-Taper (Athletic Build): For men with broad shoulders and narrow waists, the Y-Back is often more secure. The converging angle of the straps complements the natural inward slope of the trapezius muscles, preventing the straps from slipping off wide deltoids—a common annoyance with wider-set X-backs.

- The O-Shape (Heavier Midsection): For men carrying weight in the abdomen, the X-Back is mechanically superior. The 4-point stance creates a wider base of support, creating a “cage” effect that prevents the trousers from sagging at the hips (lateral dip), which is a common failure point when using a single-anchor Y-back on a larger waistline.

Driving and Sitting Comfort

If you spend hours commuting or sitting in an office chair, the placement of the rear hardware relative to your spine becomes a critical comfort factor.

- The “Spine Dig” (X-Back): The crossover point of an X-back (often reinforced with metal or double-layer leather) typically sits in the middle of the thoracic spine. When pressing against a car seat or office chair, this creates a focused pressure point that can become painful over time.

- The High Pivot (Y-Back): The Y-back joinery patch sits higher, typically between the shoulder blades (scapula). This position is usually above the contact zone of standard lumbar supports, making Y-backs significantly more comfortable for long-haul driving or desk work.

Correcting Asymmetry

Few human bodies are perfectly symmetrical. Conditions like mild scoliosis or simply having a dominant shoulder often lead to one side sitting lower than the other.

- Self-Balancing (Y-Back): The central pivot of the Y-back acts like a differential gear in a car. If one shoulder is lower, the central strap pivots slightly to equalize tension on both sides automatically without user intervention.

- Independent Rigidity (X-Back): The two straps of an X-back function independently. If you have uneven shoulders, the strap on the lower side will constantly feel loose while the other digs in, requiring you to adjust the front buckles to uneven lengths to compensate.

Hardware and Connection: Why the Patch Matters?

Regardless of whether you choose an X-back or Y-back, the entire structural integrity of the system relies on one component: The Joinery Patch. This small piece of leather acts as the “keystone” of the suspension arch. If the patch material is too thin or the stitching is weak, the kinetic energy of your movement will eventually tear the joinery apart.

Stitching Stress Tests

The junction point endures multi-directional shear force every time you move.

- The “Pull-Through” Failure: Standard cotton stitching has a tensile strength of roughly 3–5 lbs. Under sudden torque (like stumbling or lifting), these threads snap. At Hoplok, we utilize Bonded High-Tensile Nylon Thread (Tex 70 or higher), which has a breaking strength exceeding 15 lbs per stitch, effectively locking the straps into the leather patch.

- Stitch Density: We engineer our stitch count to balance security with material integrity. Too many holes perforate the leather like a stamp; too few allow gapping. The sweet spot is 6–8 stitches per inch (SPI).

Leather Thickness at the Junction

The leather patch must be rigid enough to hold its shape but flexible enough to contour to the spine.

- Thickness Specification (2.5mm – 3.0mm): We have found that leather patches thinner than 2.0mm warp and curl due to body heat and sweat. Hoplok specs patches at 2.5mm to 3.0mm. This gauge provides enough rigidity to prevent the metal adjusters from twisting while maintaining a low enough profile to sit comfortably under a jacket.

- Grain Orientation: We cut our patches with the grain running vertically to resist the primary load vector of the trousers pulling downward.

| Durability Metric | X-Back Junction (Crossover) | Y-Back Junction (Pivot Patch) |

|---|---|---|

| Stress Point Location | Mid-Back (Thoracic Spine) | Upper-Back (Scapula) |

| Stitch Failure Risk | High (Multi-directional torque) | Medium (Vertical tension primarily) |

| Comfort While Driving | Low (Metal ring can dig in) | High (Sits above seat contact) |

| Recommended Leather | Hoplok Full-Grain (Reinforced) | Hoplok Full-Grain (Flexible) |

Frequently Asked Questions

Can I wear X-back suspenders with a suit?

Yes, physically you can, but aesthetically it is discouraged. The X-back is traditionally a workwear silhouette. Furthermore, the two rear attachment points (especially if they are clips) tend to “print” through the back of a fine wool suit jacket, creating visible lumps. For suits, the Y-back is the seamless, formal standard.

Do Y-back suspenders slip off shoulders more easily?

No, in fact, the opposite is often true. Because the Y-back straps converge at a central point high on the back, they create an inward angle that naturally pulls the straps away from the edge of the shoulder. This geometry makes them excellent for men with sloping shoulders who find that straight X-back straps tend to slide off.

Which is better for big and tall men?

The X-Back is generally superior for larger frames. The 4-point anchor system offers a wider base of support, which is critical for larger waistlines. It prevents the waistband from sagging at the hips (lateral dip), a common issue when a single rear anchor point struggles to support the weight of larger trousers.

The Verdict: Stability vs. Elegance

The decision between X-back and Y-back suspenders is a calculation of your environment and activity level. If you require elegance, clean lines, and formal adherence, the Y-back is your architectural solution. If you demand maximum load stability, active range of motion, and workwear utility, the X-back is the superior tool.

Hoplok’s Engineering Perspective

Regardless of whether you choose the stability of the X or the pivot of the Y, our testing shows that the system creates a massive stress concentration at one specific location: The Junction. This leather patch is the fulcrum of the entire suspension system. If this component is made of bonded leather or stitched poorly, it becomes the definitive break point. A suspension system is only as strong as its joinery.

Ready to Reinforce Your Architecture?

If you are a manufacturer of high-end suspenders looking for precision die-cut Full-Grain Leather Patches to anchor your X or Y structures, Hoplok provides the material foundation you need. Our vegetable-tanned joinery components are engineered to withstand multi-directional torque without tearing or delaminating. Contact our engineering team for custom die patterns and stress-test data.