The demand for high-quality leather goods in the United States is stronger than ever, with the market valued at over $13 billion heading into 2025. In an era of shifting global supply chains and a renewed appreciation for local craftsmanship, brands are increasingly looking homeward to find reliable, ethical, and innovative manufacturing partners. From timeless handbags and durable belts to bespoke wallets and accessories, the “Made in the USA” label carries a weight of quality and prestige that resonates deeply with consumers. This guide is your definitive resource for navigating this thriving landscape, spotlighting the top 25 manufacturers who are setting the standard for American leather craftsmanship.

To identify the top 25 US leather goods manufacturers, we analyzed key criteria including craftsmanship, material quality, innovation, and sustainability, using data from industry sources like Thomasnet and expert reviews. This definitive 2025 list features heritage giants like Horween alongside rising, service-oriented players like Hoplok Leather, providing a comprehensive guide for brands seeking a reliable American partner that blends global experience with domestic production values.

Choosing a manufacturing partner is one of the most critical decisions a brand can make. It impacts everything from product quality and brand reputation to logistical efficiency and ethical standing. This comprehensive list is designed to be more than just a directory; it’s a strategic tool. We will explore the benefits of manufacturing in the USA, provide a step-by-step guide to selecting the right partner, and offer in-depth profiles of the companies that are leading the way. Whether you’re a startup looking for flexible MOQs or an established brand seeking a premier production partner, this guide will provide the insights you need to make an informed decision.

Why Choose Leather Goods Manufacturers in the USA?

Superior Quality and Standards

The “Made in the USA” tag is synonymous with a legacy of quality. American leather manufacturing is built on a foundation of heritage craftsmanship, where attention to detail is paramount. This focus results in a superior product from start to finish. Key advantages include:

- Exceptional Construction: Unlike mass-production facilities that may prioritize speed, many US workshops emphasize handcrafting techniques, resulting in better stitching, finer finishing, and a more durable final product.

- Premium Raw Materials: American makers often have direct access to high-quality, full-grain hides from world-renowned domestic tanneries like Horween, ensuring a top-tier foundation for your goods.

The Ethical and Sustainable Edge

In an era of conscious consumerism, transparency is key. US manufacturers operate under stringent labor laws and are increasingly adopting eco-friendly practices, which provides a powerful story for your brand.

- Fair Labor Practices: Strict federal and state laws guarantee fair wages and safe working conditions, providing crucial brand protection against the risks of unregulated overseas factories.

- Environmental Responsibility: Many American factories are leading the charge in sustainability, using methods like vegetable tanning, water recycling, and responsible chemical management.

Logistics and Economic Benefits

Working with a domestic partner simplifies your supply chain, reduces risk, and strengthens the local economy. It’s a decision that benefits both your business and your community.

- Simplified Supply Chain: Domestic production eliminates the complexities of international shipping, customs, and volatile tariffs, reducing the risk of costly delays.

- Faster Turnaround: Shorter lead times and quicker shipping mean your brand can be more agile and responsive to market trends and customer demand.

- Support for the Local Economy: Manufacturing in the USA supports American jobs and a skilled workforce, a value proposition that strongly appeals to many consumers.

Innovation and Customization

American manufacturing is not just about tradition; it’s also a hub of innovation. This environment fosters a high degree of customization and collaboration for brands.

- Technological Advancement: US companies are often at the forefront of innovation, utilizing advanced cutting techniques and developing novel material hybrids.

- Deep Collaboration: Domestic partners are typically more accessible and willing to work closely with brands on custom designs and private label development, offering a level of partnership that can be difficult to achieve overseas.

History and Evolution of Leather Goods Manufacturing in the USA

The US leather industry evolved from essential colonial craft to a powerhouse during the Industrial Revolution, with heritage tanneries like Horween (est. 1905) setting global standards. After a mid-20th century decline due to global competition, the industry has seen a modern resurgence. Today, it is defined by a focus on high-quality craftsmanship, sustainability, and technological innovation, proving its resilience and adaptability in the 21st-century market.

Origins to the Industrial Boom

The story of American leather manufacturing is woven into the fabric of the nation itself. Tanning began as a vital local craft in colonial America, but the 19th century marked a massive transformation. The industrial boom, fueled by events like the Civil War, scaled up demand and turned regions like the Catskills and Wisconsin into major tanning hubs. This era saw the birth of iconic companies like Filson (1897) and the Horween Leather Company (1905), which built their legacies on unfailing quality. The industrial peak culminated in World War II, when US manufacturers became a critical part of the war effort, cementing a reputation for durable, high-performance goods.

Modern Shifts (2000–2025)

The latter half of the 20th century was challenging due to global competition, but the 21st century has sparked a powerful resurgence. This revival is driven by several key shifts:

- The Artisanal Renaissance: E-commerce empowered smaller, artisanal brands to connect directly with a global audience, renewing interest in handcrafted American goods.

- A Shift from Fast Fashion: Consumers began prioritizing longevity and quality, seeking out products with a story and a guarantee of durability.

- A Focus on Sustainability: Growing consumer awareness has pushed US manufacturers to the forefront of sustainable practices, including ethical sourcing and eco-friendly tanning.

Influential Milestones and Current Dynamics

Today, the US leather goods industry is a dynamic blend of heritage and innovation. The focus has shifted from mass production to high-value, quality-driven manufacturing. Despite global competition, the US market continues to show steady growth, remaining a significant economic contributor. Modern American manufacturing now blends tradition with technology, using advanced techniques to enhance design and precision, making it a compelling choice for brands seeking the very best.

Key Factors to Consider When Choosing a Leather Goods Manufacturer

When choosing a US manufacturer, evaluate a balance of factors. Prioritize their production capacity and scale, ensuring their MOQs and turnaround times fit your business model. Scrutinize their quality control, material sourcing, and certifications (e.g., ISO 9001). Assess their customization capabilities for private label needs and their commitment to sustainability. Finally, weigh their reputation and pricing against the logistical advantages of domestic production.

Capacity and Scale

First, ensure a potential partner can meet your production needs. This involves two key questions: What are their Minimum Order Quantities (MOQs), and what are their typical turnaround times? Some artisanal workshops are perfect for small-batch production but can’t handle large orders, while bigger factories might have high MOQs unsuitable for startups. A great partner is one whose scale aligns with yours.

Quality Control and Material Sourcing

Never compromise on quality. A reputable manufacturer will have a robust quality control system with checkpoints at every stage. Key things to verify include:

- Robust QC Systems: Ask them to walk you through their multi-stage quality control process.

- Certifications: Look for internationally recognized certifications for quality management (ISO 9001) and ethical practices.

- Premium Materials: Inquire about their hide sourcing. Can they procure high-quality, full-grain leather from reputable tanneries?

Customization and Private Label Capabilities

Your manufacturer should be a true partner in bringing your vision to life. A flexible partner who can offer guidance on design, materials, and construction is invaluable. Assess their capabilities:

- Design Collaboration: Can they work from your tech packs and offer expert guidance?

- Private Label Services: Do they have experience producing goods for other brands and understand the nuances of private label manufacturing?

Sustainability and Ethical Practices

In 2025, sustainability is non-negotiable. Ask potential partners about their environmental and ethical practices to ensure they align with your brand’s values.

- Eco-Friendly Processes: Inquire about their tanning methods, water usage, and chemical waste management.

- Social Compliance Audits: Request to see their SMETA or BSCI reports to verify they adhere to fair labor standards.

Pricing, Logistics, and Compliance

While cost is important, it should be considered in context. The advantages of faster shipping, no import tariffs, and easier logistics can often offset a higher unit cost from a US manufacturer.

Ask for transparent, itemized pricing to understand what you’re paying for. Also, ensure they are compliant with any specific regulations your products require, such as California’s Prop 65.

Reputation and Customer Support

A factory’s reputation is its most valuable asset. Look for a partner with a proven track record, positive reviews on platforms like Thomasnet, and a history of working with brands in your market. Their communication style during your initial inquiry is a critical test of the professionalism and support you can expect.

Factors Table: US vs. Global Manufacturing

| Factor | US Manufacturers | Typical Overseas Manufacturers |

|---|---|---|

| Quality Control | High, with easy on-site access for verification | Variable; can be difficult and expensive to monitor |

| Lead Times | Shorter (weeks) | Longer (months), with risk of shipping delays |

| Ethical/Sustainability | High, due to strict regulations | Variable; requires careful vetting and audits |

| Cost | Higher unit cost | Lower unit cost |

| Communication | Easier (no language barrier, same time zones) | Can be challenging due to language and time differences |

Step-by-Step Guide to Selecting a US Leather Goods Manufacturer

To select a US leather goods manufacturer, start with a clear needs assessment of your product, volume, and budget. Next, research and shortlist potential partners using directories like Thomasnet. Critically evaluate their samples for quality. If possible, conduct a facility audit to check their production and ethical standards. Finally, negotiate a detailed contract and focus on building a strong, collaborative long-term partnership.

Step 1: Needs Assessment

Before you begin your search, you need a clear vision. Define the specifics of your project. What exact products do you want to make? What are your target materials and price point? Having a detailed plan will make it much easier to identify manufacturers that are a good fit and will allow you to have a more productive initial conversation.

Step 2: Research and Shortlist

With your plan in hand, begin your research. Use online directories like Thomasnet, read industry publications, and check reviews to build an initial list of potential partners. Look for companies whose specialties align with your product needs. From your initial research, create a shortlist of 5-10 manufacturers that seem like the best fit to move forward with.

Step 3: Sample Evaluation

This is a critical step. You must get your hands on a potential partner’s work to truly judge its quality. Request samples of their previous work or, ideally, have them create a prototype of your product. When you receive the sample, scrutinize every detail: the quality of the leather, the precision of the stitching, the feel of the hardware, and the overall construction. The sample is a direct reflection of the quality you can expect from a full production run.

Step 4: Facility Audits

If possible, conduct an on-site visit to the factory. This gives you invaluable insight into their operations, their commitment to quality, and their working conditions. If a visit isn’t feasible, ask for a virtual tour or hire a local sourcing agent to conduct an audit on your behalf. This step is crucial for verifying their capabilities and ensuring their ethical standards align with your brand’s values.

Step 5: Negotiation

Once you’ve found a manufacturer that meets your quality and ethical standards, it’s time to finalize the details. Negotiate the pricing, MOQs, and payment terms. Most importantly, work with them to create a detailed manufacturing agreement that clearly outlines all product specifications, quality standards, and production timelines. This contract is your primary tool for ensuring a successful outcome.

Step 6: Partnership Building

Remember, your relationship with your manufacturer is a partnership, not just a transaction. Building a strong, collaborative relationship based on clear communication and mutual respect is the key to long-term success.

Provide constructive feedback, be clear about your expectations, and work together to solve any challenges that arise. A strong partnership is the foundation of a resilient and successful supply chain. For additional resources, platforms like Makersrow can also be valuable for connecting with American manufacturers.

The Top 25 Leather Goods Manufacturers in the USA

Our 2025 list of the top 25 US leather goods manufacturers was compiled based on rigorous criteria, including product quality, innovation, sustainability, and market reputation. This curated list features a mix of iconic heritage tanneries, renowned artisanal brands, and versatile private-label specialists. Each company has been selected for its commitment to excellence and its significant contribution to the American leather industry.

Here are the companies that define American leather craftsmanship in 2025. We’ve selected them based on a comprehensive review of their market presence, product quality, innovation, and commitment to sustainable and ethical practices. This list includes both iconic, century-old tanneries that supply the world’s best brands and smaller, artisanal workshops that produce exceptional handcrafted goods.

1. Horween Leather Company

- Established: 1905

- Location: Chicago, IL

- Website: horween.com

- Product Overview: Horween is not a finished goods manufacturer but one of America’s oldest and most revered tanneries. They are the source behind the world-class leather used by many of the top brands on this list. Their business is producing premium hides for footwear, sporting goods, bags, and accessories.

- Key Products: They are globally famous for their proprietary leathers, including the rich, durable Chromexcel® and the highly coveted Genuine Shell Cordovan™.

- Manufacturing Techniques and Expertise: With over a century of experience, Horween excels in traditional, hands-on tanning methods. They combine old-world formulas with modern techniques to create leathers of unparalleled quality and character. They are one of the few tanneries in the US that still processes hides from their raw state to a fully finished product in-house.

- Materials Used: Their primary materials are native US cowhides and horsehides. They are particularly renowned for their expertise in tanning horsehide to produce the unique and durable Shell Cordovan.

2. Tanner Goods

- Established: 2006

- Location: Portland, OR

- Website: tannergoods.com

- Product Overview: Tanner Goods is a design-led brand and manufacturer of heritage-quality leather goods and accessories. They focus on a philosophy of “Worth Holding Onto,” creating durable, minimalist products that are built for a lifetime of use. They serve both direct-to-consumer and wholesale markets.

- Key Products: Their collection includes the iconic Journeyman Wallet, a variety of durable belts, bags, and other everyday carry items.

- Manufacturing Techniques and Expertise: The company champions traditional craftsmanship. Their products feature meticulous details like hand-burnished edges and sturdy stitch work. They combine timeless aesthetics with modern, functional design, creating products that are both beautiful and practical.

- Materials Used: Tanner Goods is well-known for its use of premium, vegetable-tanned leathers, which are sourced from US tanneries. They also incorporate other high-quality materials like waxed canvas and solid brass hardware into their designs.

3. Allen Edmonds

- Established: 1922

- Location: Port Washington, WI

- Website: allenedmonds.com

- Product Overview: Allen Edmonds is a heritage American brand and manufacturer, world-renowned for its premium men’s footwear. While shoes are their specialty, they also produce a full line of high-quality leather accessories, including belts, wallets, and briefcases, designed to complement their footwear collections.

- Key Products: Their iconic Goodyear-welted dress shoes like the Park Avenue are legendary. Their dress belts are designed to perfectly match the leathers and finishes of their shoes.

- Manufacturing Techniques and Expertise: The company is a master of the 360° Goodyear Bench Welt construction method, a time-honored technique that makes shoes durable, water-resistant, and easily recraftable. This commitment to quality construction extends to their accessories, which are made in their US factory.

- Materials Used: Allen Edmonds uses premium, imported materials, including high-end calfskin and other fine leathers, to craft their products. They are known for their meticulous material selection and quality control.

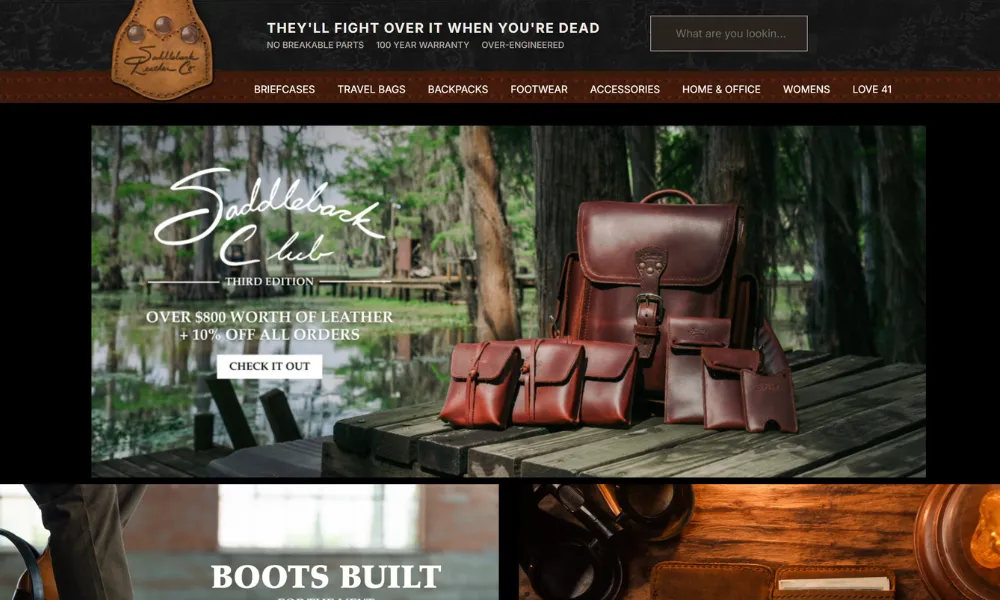

4. Saddleback Leather

- Established: 2003

- Location: Fort Worth, TX

- Website: saddlebackleather.com

- Product Overview: Saddleback Leather has built a legendary reputation on one core principle: extreme durability. Famously over-engineered and backed by a 100-year warranty, their products are designed to be heirloom pieces. Their motto, “They’ll fight over it when you’re dead,” perfectly encapsulates their brand ethos of creating rugged, lifelong goods.

- Key Products: They are best known for their robust bags, including the Classic Leather Briefcase, backpacks, and duffel bags.

- Manufacturing Techniques and Expertise: The company’s expertise lies in over-engineering for longevity. They use a minimal number of leather pieces to reduce seams, employ strong, continuous filament polyester thread (the kind used for parachutes), and avoid breakable parts like zippers and magnets in favor of sturdy buckles and clasps.

- Materials Used: Saddleback exclusively uses thick, tough, full-grain cowhide leather. They pair this with marine-grade stainless steel or nickel-plated brass hardware to ensure every component is as durable as the leather itself.

5. Filson

- Established: 1897

- Location: Seattle, WA

- Website: filson.com

- Product Overview: Filson is a legendary American heritage brand that has been outfitting outdoor enthusiasts, workers, and adventurers for over a century. They are manufacturers of unfailing goods, specializing in rugged, durable apparel, luggage, and accessories built to withstand the harshest conditions.

- Key Products: Their iconic Rugged Twill Original Briefcase and Mackinaw Cruiser Jacket are world-renowned. They also produce a range of durable leather belts and wallets.

- Manufacturing Techniques and Expertise: Filson’s expertise lies in creating hybrid products that masterfully combine different materials for maximum performance. Their manufacturing process emphasizes strength and functionality, with heavy-duty stitching and reinforced stress points.

- Materials Used: They are famous for their proprietary materials like rugged Tin Cloth and Mackinaw Wool, which they expertly pair with premium, vegetable-tanned Bridle Leather for straps, handles, and reinforcements.

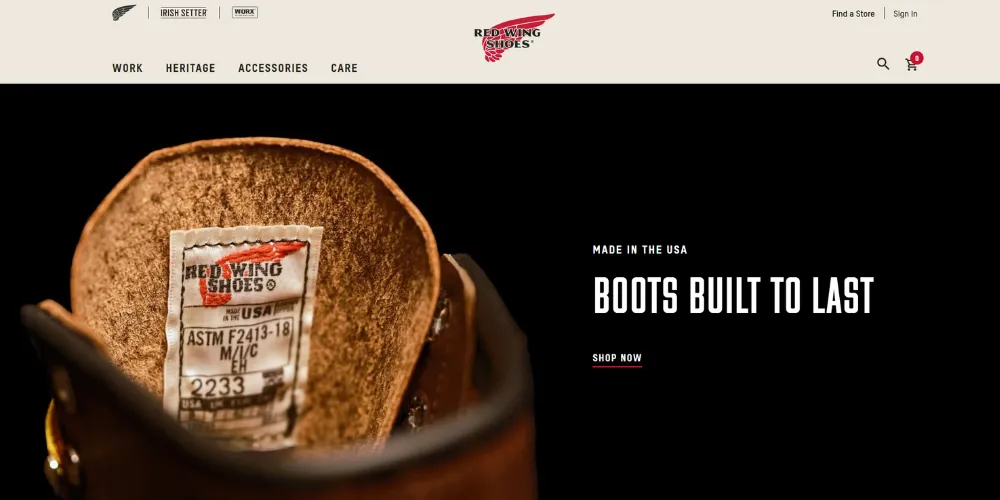

6. Red Wing Shoes

- Established: 1905

- Location: Red Wing, MN

- Website: redwingshoes.com

- Product Overview: Red Wing is a cornerstone of American workwear, primarily known for manufacturing high-quality, durable work boots. Their expertise in footwear has naturally extended to a line of heritage leather accessories, including belts and wallets, that reflect the same commitment to quality and longevity.

- Key Products: The Iron Ranger and Classic Moc boots are iconic. Their leather belts are designed to be just as tough, often mirroring the leather types used in their footwear.

- Manufacturing Techniques and Expertise: With over a century of experience in crafting durable footwear, Red Wing has mastered the art of working with thick, tough leathers. Their expertise in cutting, stitching, and finishing for maximum durability is applied to their entire range of leather goods.

- Materials Used: Red Wing owns its own tannery, S.B. Foot Tanning Co., giving them complete control over their leather quality. They use a variety of full-grain, oil-tanned leathers that are known for their durability and water resistance.

7. Coach

- Established: 1941

- Location: New York, NY

- Website: coach.com

- Product Overview: Coach is one of America’s most iconic luxury brands, evolving from a small family-run workshop into a global fashion powerhouse. They manufacture a wide range of leather goods, including handbags, wallets, footwear, and accessories, known for their accessible luxury and classic American style.

- Key Products: They are famous for their extensive line of women’s handbags, such as the Tabby and Rogue bags, as well as men’s briefcases and belts.

- Manufacturing Techniques and Expertise: Coach has a long history of leather craftsmanship, particularly with their signature “glove-tanned” leather. While a significant portion of their production is now overseas, the brand maintains a strong focus on quality design and is increasingly highlighting its American heritage and commitment to more sustainable production practices.

- Materials Used: The brand is known for its use of high-quality materials, including their signature glove-tanned leather, refined pebble leather, and a growing range of sustainable materials.

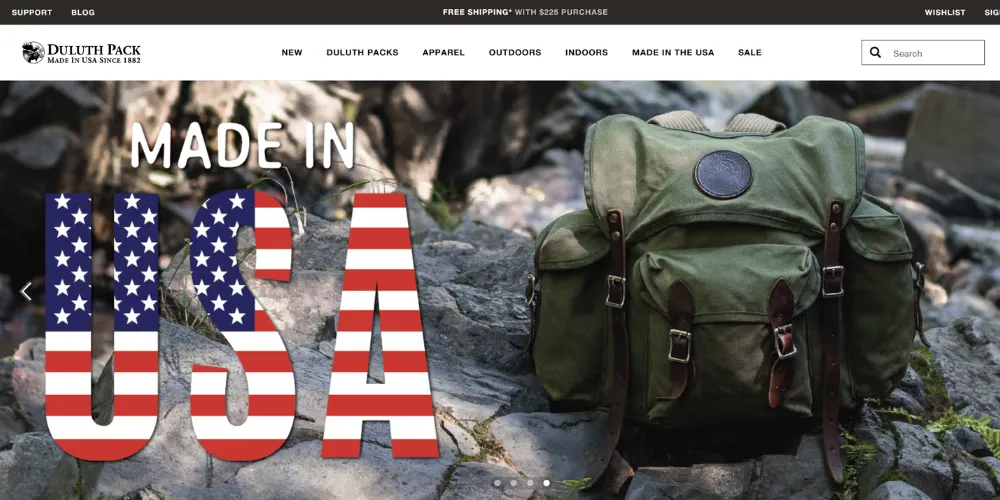

8. Duluth Pack

- Established: 1882

- Location: Duluth, MN

- Website: duluthpack.com

- Product Overview: As the oldest canvas and leather bag manufacturer in the USA, Duluth Pack has a storied history of creating handcrafted, built-to-last packs and bags. Every product is made in their Minnesota factory and comes with a lifetime guarantee, a testament to their confidence in their craftsmanship.

- Key Products: Their classic canoe packs and the Scout Pack are iconic. They also produce a range of durable totes, duffels, and briefcases.

- Manufacturing Techniques and Expertise: Duluth Pack’s expertise is in the time-tested combination of rugged canvas and durable leather. Their bags are handcrafted by skilled artisans, with each piece signed by the person who made it. They use heavy-duty stitching and hand-hammered rivets to ensure maximum durability.

- Materials Used: Their signature style combines tough, rugged canvas with premium, rich full-grain leather for straps, reinforcements, and details. They also use high-quality hardware, including solid brass buckles and snaps.

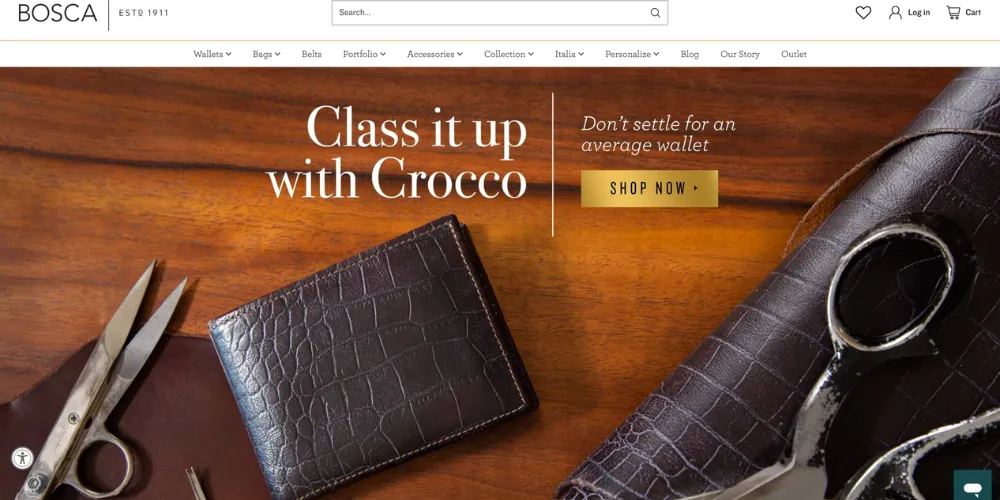

9. Bosca

- Established: 1911

- Location: Springfield, OH

- Website: bosca.com

- Product Overview: Bosca is a heritage brand that combines American design with Italian artistry, specializing in fine leather wallets, bags, and accessories. With over a century of experience, they are known for creating elegant, timeless pieces for the modern professional.

- Key Products: They are particularly renowned for their extensive collection of finely crafted wallets, card cases, and their classic Old Leather Collection of briefcases and bags.

- Manufacturing Techniques and Expertise: Bosca’s expertise lies in working with fine, hand-stained Italian leathers. Their process emphasizes meticulous details, such as turned-edge construction and precise stitching, to create a refined, luxurious finish.

- Materials Used: The brand is famous for its use of high-quality, vegetable-tanned Italian leathers. They select hides that are known for their softness, rich color, and ability to develop a beautiful patina over time.

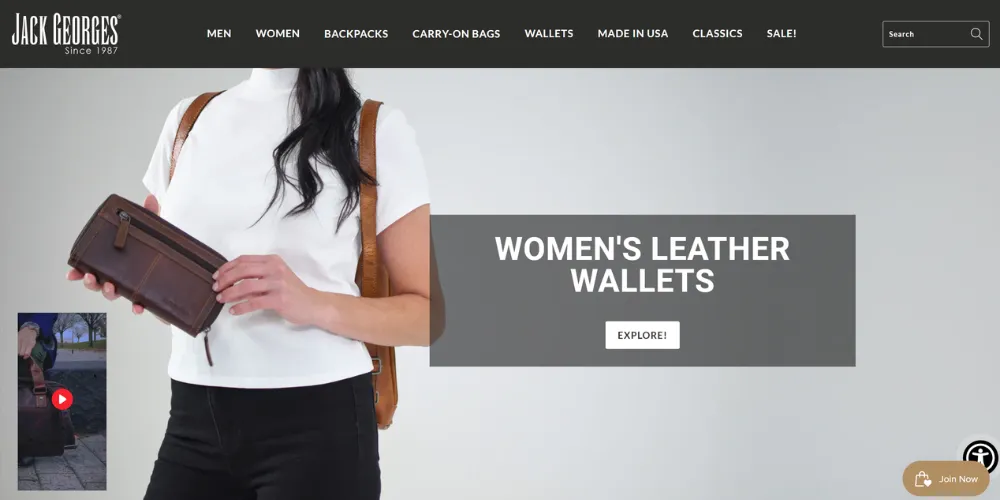

10. Jack Georges

- Established: 1987

- Location: New York, NY

- Website: jackgeorges.com

- Product Overview: Jack Georges is a family-owned manufacturer that has been crafting high-quality, functional business cases and accessories for over 30 years. Their products are designed for the discerning professional, blending classic style with practical features and are backed by a lifetime warranty.

- Key Products: The company is a specialist in professional bags, including their durable leather briefcases, laptop bags, and portfolios.

- Manufacturing Techniques and Expertise: Their expertise is in creating highly functional, organized bags for the modern professional. They combine traditional leatherworking techniques with innovative design features to create products that are both stylish and practical for everyday business use.

- Materials Used: They use a variety of high-quality leathers, including American steerhide and scratch-resistant Italian leathers, to ensure their products are both beautiful and built to withstand the rigors of daily use.

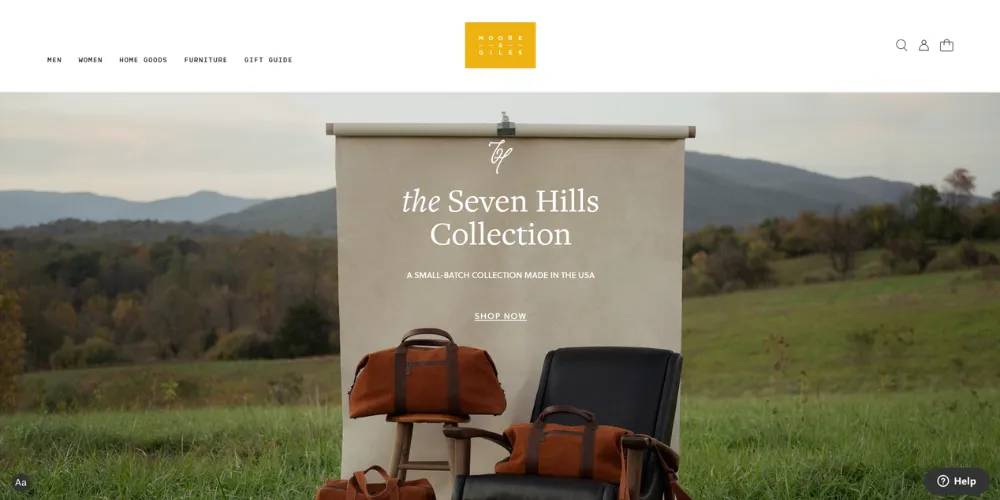

11. Moore & Giles

- Established: 1933

- Location: Lynchburg, VA

- Website: mooreandgiles.com

- Product Overview: Originally founded as a leather supplier for the furniture industry, Moore & Giles has evolved into a premier designer and manufacturer of luxury leather bags, accessories, and home goods. Their products are known for their exceptional quality and timeless, sophisticated design.

- Key Products: They are known for their luxurious travel bags, particularly the Benedict Weekend Bag, as well as a range of high-end briefcases, totes, and accessories.

- Manufacturing Techniques and Expertise: With their deep roots as a leather tannery and supplier, their primary expertise is in the leather itself. They have an unparalleled understanding of how to select and work with the world’s finest hides to create products of exceptional beauty and quality.

- Materials Used: Moore & Giles is renowned for its use of unique and luxurious leathers, including their signature Baldwin and Titan Milled leathers, which are known for their incredibly soft feel and rich, natural character.

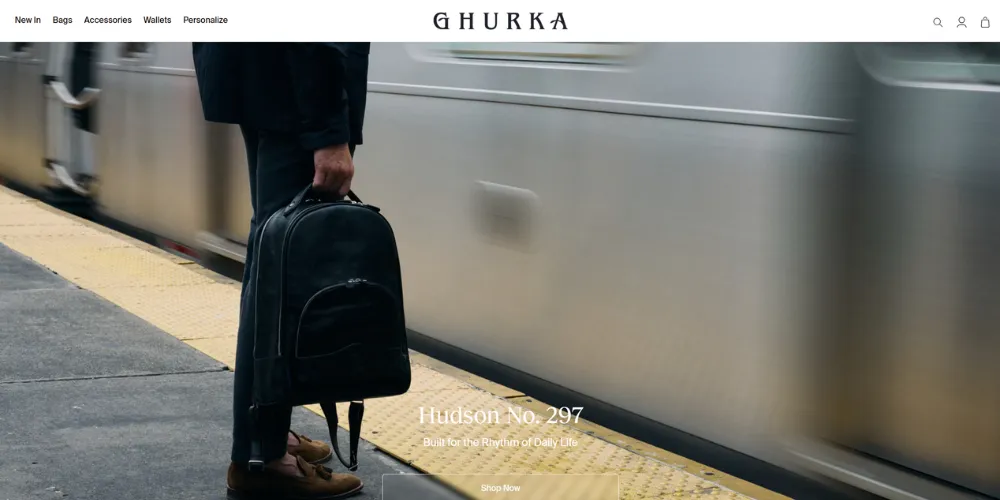

12. Ghurka

- Established: 1975

- Location: New York, NY

- Website: ghurka.com

- Product Overview: Ghurka is a luxury American brand that creates handcrafted leather and twill bags and accessories with a distinct, military-inspired heritage. Each piece is handmade by master artisans and is designed to be a rugged, lifelong companion.

- Key Products: Their iconic designs include the Examiner No. 5 briefcase and the Cavalier series of duffel bags.

- Manufacturing Techniques and Expertise: The brand’s expertise lies in its meticulous, time-honored construction methods. Each Ghurka bag is individually numbered and registered, a testament to its artisanal, small-batch production process. They use durable stitching and solid brass hardware to ensure every bag can withstand a lifetime of travel and adventure.

- Materials Used: Ghurka is known for its signature combination of durable twill fabric and fine, vegetable-tanned leather trim. This pairing creates a look that is both rugged and refined.

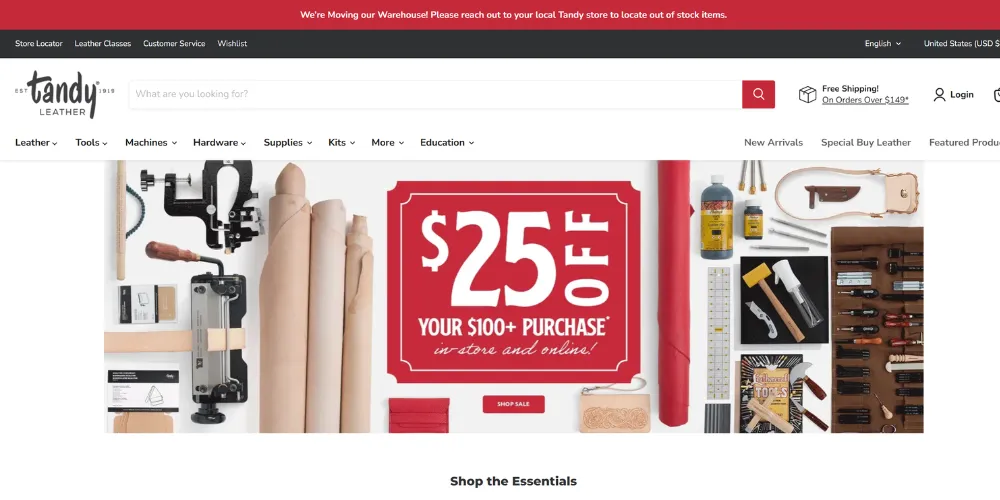

13. Tandy Leather

- Established: 1919

- Location: Fort Worth, TX

- Website: tandyleather.com

- Product Overview: Tandy Leather is a unique company on this list, as they are primarily a supplier and resource for the leathercraft community rather than a finished goods manufacturer. They are one of the world’s largest distributors of leather, tools, kits, and supplies for hobbyists and professional leatherworkers.

- Key Products: They sell everything needed for leatherworking, including vegetable-tanned leather hides, hardware, dyes, and a vast array of project kits for making wallets, belts, and more.

- Manufacturing Techniques and Expertise: While they don’t manufacture finished goods on a large scale, their expertise lies in sourcing and providing a comprehensive range of materials and tools for the craft. They are a vital part of the American leather industry, empowering thousands of individual makers and small businesses.

- Materials Used: They offer a massive variety of leathers, from premium full-grain hides for professional work to more affordable options for beginners, making them a one-stop-shop for the entire leathercrafting community.

14. Ralph Lauren

- Established: 1967

- Location: New York, NY

- Website: ralphlauren.com

- Product Overview: Ralph Lauren is a global icon of American style, manufacturing a vast range of luxury apparel, home goods, and accessories. Their leather goods collections embody a sophisticated, aspirational lifestyle, blending classic equestrian and Americana influences with modern luxury.

- Key Products: The brand is famous for its high-end handbags, such as the RL50 and Ricky bags, as well as a full range of men’s and women’s belts, wallets, and footwear.

- Manufacturing Techniques and Expertise: As a major fashion house, Ralph Lauren’s expertise is in design, branding, and curating a luxury experience. They partner with high-end workshops, many in Italy, to produce their goods, ensuring the craftsmanship meets their exacting standards for quality and finish.

- Materials Used: They utilize a wide array of premium materials, including supple calfskin, durable saddle leather, and exotic skins like alligator, all selected to convey a sense of timeless luxury.

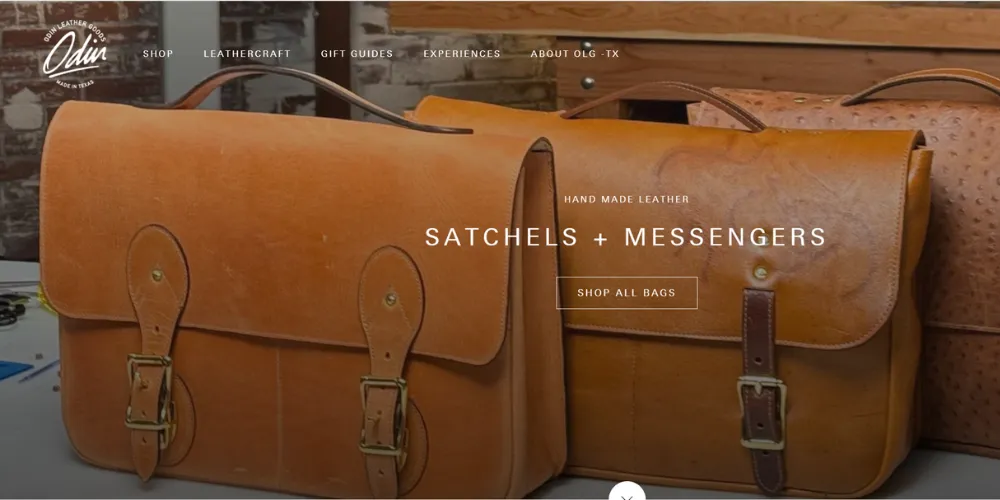

15. Odin Leather Goods

- Established: 2012

- Location: Texas, USA

- Website: odinleathergoods.com

- Product Overview: Odin Leather Goods is an artisanal manufacturer that creates rugged, handcrafted leather products designed for a lifetime of use. With a focus on traditional techniques and a distinctly Texan aesthetic, they produce a range of goods that are both functional and full of character.

- Key Products: They are known for their durable tote bags, crossbody purses, wallets, and a wide variety of handcrafted belts.

- Manufacturing Techniques and Expertise: Their expertise is in hands-on, traditional leatherworking. Every item is cut, stitched, and finished by hand in their Texas workshop, ensuring a high level of attention to detail and a unique, artisanal quality in every piece.

- Materials Used: Odin primarily uses high-quality, full-grain leathers sourced from American tanneries. This commitment to domestic materials ensures their products are durable and develop a rich, beautiful patina over time.

16. Mitchell Leather

- Established: 1969

- Location: Milwaukee, WI

- Website: mitchell-leather.com

- Product Overview: Mitchell Leather is a family-owned business with a multi-generational history of crafting exceptional, custom leather goods. They are particularly famous for their money clip wallets and offer a range of products that showcase their deep expertise in leatherworking.

- Key Products: Their most famous product is the Money Clip Wallet, often made from premium Shell Cordovan. They also produce briefcases, belts, and other custom accessories.

- Manufacturing Techniques and Expertise: With decades of experience, Mitchell Leather’s expertise is in precision craftsmanship and working with the world’s finest leathers. Their ability to create perfectly stitched, beautifully finished custom items is a hallmark of their brand.

- Materials Used: They are known for using elite-tier leathers, including the highly sought-after Shell Cordovan from Horween, as well as other premium full-grain and vegetable-tanned leathers.

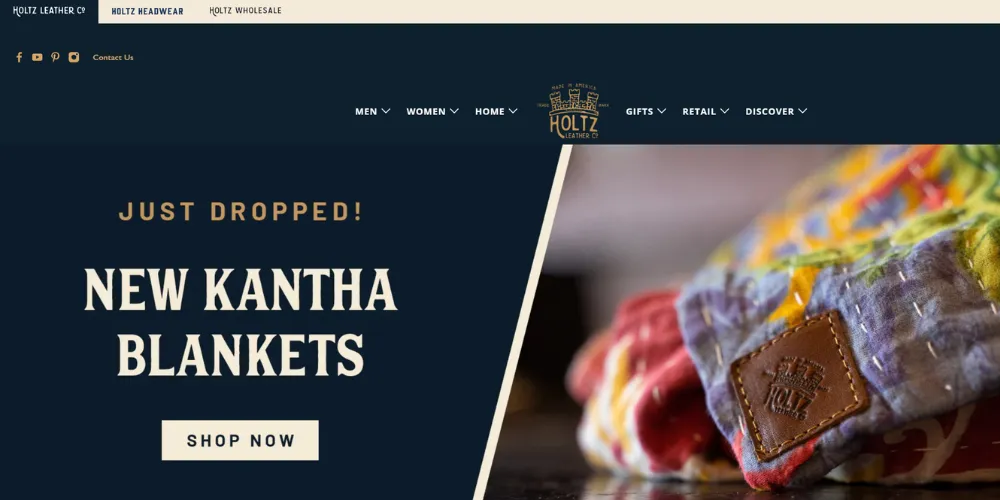

17. Holtz Leather Co.

- Established: 2012

- Location: Huntsville, AL

- Website: holtzleather.com

- Product Overview: Holtz Leather Co. is a family-owned and operated business that specializes in personalized, handcrafted leather goods. They have built a strong brand around creating meaningful, custom items that are perfect for gifting and personal use, all made in their Alabama workshop.

- Key Products: They are well-known for their personalized journals, portfolios, wallets, and family Bibles, often featuring custom monograms and logos.

- Manufacturing Techniques and Expertise: Their primary expertise lies in personalization. They have mastered techniques like laser engraving and fire-branding to create unique, custom pieces for their customers, combining modern technology with traditional leathercraft.

- Materials Used: They use high-quality, durable full-grain American leather, ensuring that their personalized products are not only sentimental but also built to last.

18. Cut and Stitch

- Established: 2012

- Location: New York, NY

- Website: cutandstitch.com

- Product Overview: Cut and Stitch is a premier private-label manufacturer specializing in creating custom leather goods and accessories for other brands. They offer a full-service solution, from design and development to sourcing and production, making them a key partner for businesses looking to launch their own leather goods line.

- Key Products: They do not have their own product line but manufacture a wide range of goods for clients, including belts, wallets, bags, and small accessories.

- Manufacturing Techniques and Expertise: Their expertise is in full-service, private-label production. They guide brands through the entire manufacturing process, from initial concept to finished product, with a focus on quality control and meeting client specifications.

- Materials Used: They have the capability to source a wide variety of materials based on their clients’ needs, including different grades of leather, hardware, and other components, to match a brand’s target cost and quality level.

19. GFG Bag Manufacturer

- Established: Data not specified

- Location: Tennessee, USA

- Website: gfgbagmanufacturer.com

- Product Overview: GFG Bag Manufacturer is a US-based company that specializes in custom bag and accessory production for a diverse range of clients. They position themselves as a flexible partner for brands of all sizes, offering services that cover the entire production lifecycle from design to delivery.

- Key Products: Their focus is on custom manufacturing, producing a variety of bags including totes, backpacks, and specialty bags based on client designs.

- Manufacturing Techniques and Expertise: Their expertise lies in their ability to handle custom, small-batch production runs. They work closely with clients on pattern making, prototyping, and material selection to ensure the final product matches the brand’s vision.

- Materials Used: They work with a wide array of materials as specified by their clients, including various types of leather, canvas, nylon, and other textiles, to create fully customized products.

20. Portchester USA

- Established: 1978

- Location: New York, NY

- Website: portchesterusa.com

- Product Overview: Portchester USA is a large-scale, private-label manufacturer of handbags and accessories. With decades of experience, they are a major player in the industry, capable of handling high-volume production for established brands while maintaining a commitment to quality.

- Key Products: They specialize in the mass production of private-label handbags, wallets, and small leather goods for major retail brands.

- Manufacturing Techniques and Expertise: Their expertise is in managing large-scale production runs efficiently. They have a well-established supply chain and sophisticated production management systems that allow them to deliver high-volume orders on time and to specification.

- Materials Used: They are equipped to work with a wide range of materials, from genuine and synthetic leathers to various textiles, to meet the specific cost and quality requirements of their large-scale retail clients.

21. Softline Brand Partners

- Established: 2008

- Location: California, USA

- Website: softlinebrandpartners.com

- Product Overview: Softline Brand Partners is a full-service design, development, and manufacturing firm with a strong focus on sustainability and ethical production. They partner with brands to create a wide range of products, including bags, accessories, and apparel.

- Key Products: They produce custom bags, backpacks, and accessories for brands that prioritize sustainable and ethically sourced materials.

- Manufacturing Techniques and Expertise: Their key expertise is in sustainable product development. They help brands navigate the complexities of sourcing eco-friendly materials and setting up ethical supply chains, making them a go-to partner for conscious brands.

- Materials Used: They are proficient in working with a variety of sustainable materials, including recycled fabrics, organic cotton, and innovative, eco-friendly leather alternatives.

22. Fifield, Inc.

- Established: 1924

- Location: Hingham, MA

- Website: fifieldfabrics.com

- Product Overview: Fifield, Inc. is a specialized manufacturer and distributor of industrial and specialty fabrics, including a range of leatherette and faux leather materials. Their focus is less on fashion and more on providing materials for packaging, display, and industrial applications.

- Key Products: They supply materials like faux suede, leatherette, and flocked fabrics used for jewelry displays, luxury packaging, and bookbinding.

- Manufacturing Techniques and Expertise: Their expertise lies in material converting services, such as adhesive backing, die-cutting, and custom slitting, to prepare their materials for specific industrial uses.

- Materials Used: They specialize in a wide range of non-animal-based materials, including various grades of synthetic leather (PU and PVC) and other specialty textiles.

23. Silver Creek Leather Co.

- Established: 2002

- Location: Indiana, USA

- Website: silvercreekleather.com

- Product Overview: Similar to Tandy, Silver Creek Leather Co. is a major supplier to the leathercrafting industry. They manufacture and distribute a wide range of leather, tools, and kits, serving both individual hobbyists and commercial businesses.

- Key Products: They are known for their Realeather® brand of craft leathers, DIY kits for making items like journals and moccasins, and a comprehensive selection of leatherworking tools.

- Manufacturing Techniques and Expertise: Their expertise is in sourcing, processing, and packaging leather for the craft market. They excel at creating accessible, user-friendly kits that empower people to create their own leather goods.

- Materials Used: They offer a vast array of leathers, including traditional vegetable-tanned hides, colorful finished leathers, and suede, catering to a wide range of crafting projects.

24. American Leather Operations, LLC

- Established: 1990

- Location: Dallas, TX

- Website: americanleather.com

- Product Overview: American Leather is a leading manufacturer of high-end, custom leather furniture. While their primary focus is on large items like sofas and chairs, their deep expertise in leather also extends to the production of high-quality accessories and home goods.

- Key Products: They are famous for their innovative and comfortable leather sofas and recliners. Their expertise also allows them to produce smaller accessories with the same commitment to quality.

- Manufacturing Techniques and Expertise: The company is a pioneer in lean manufacturing and just-in-time production techniques, allowing them to create custom furniture with industry-leading speed. They utilize advanced, precision cutting technology to maximize hide usage and ensure perfect results.

- Materials Used: They source premium hides from around the world and offer an extensive library of over 100 types of full-grain and top-grain leathers in a vast array of colors and finishes.

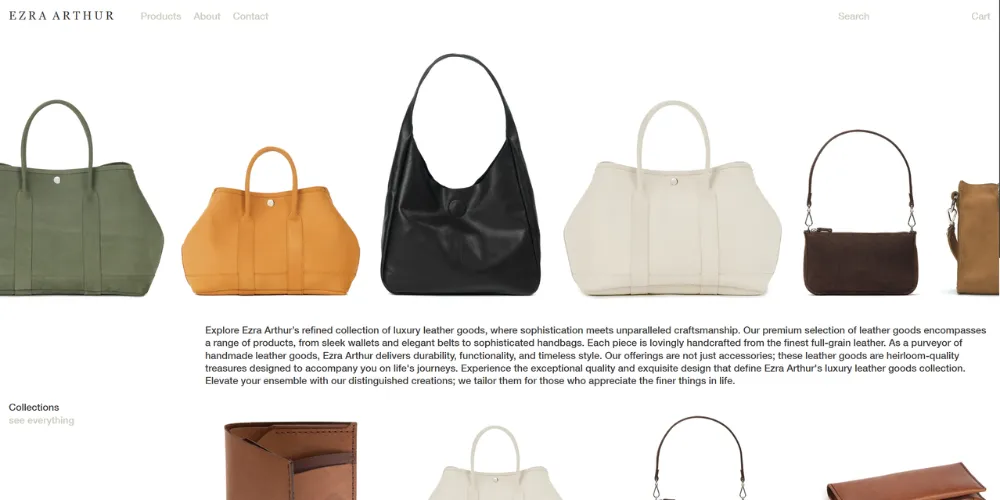

25. Ezra Arthur

- Established: 2012

- Location: USA

- Website: ezraarthur.com

- Product Overview: Ezra Arthur is a modern American heritage brand that manufactures meticulously crafted, minimalist leather goods designed for a lifetime of use. They are committed to US-based manufacturing and back their products with a lifetime warranty.

- Key Products: They are best known for their exceptionally slim and well-designed wallets, such as the No. 6 Wallet, as well as a curated selection of bags, belts, and accessories.

- Manufacturing Techniques and Expertise: Their expertise is in combining modern, minimalist design with traditional, high-quality construction. Every product is handcrafted in their workshop, showcasing a commitment to precision and detail.

- Materials Used: Ezra Arthur uses only the finest American-sourced materials, including premium full-grain, vegetable-tanned leathers from renowned tanneries like Horween.

Top 25 Manufacturers: At a Glance

| Manufacturer | Location | Primary Specialty | Key Feature |

|---|---|---|---|

| Horween Leather Company | Chicago, IL | Premium Tannery | Iconic Chromexcel® & Shell Cordovan™ |

| Tanner Goods | Portland, OR | Artisanal Goods | Vegetable-tanned leather craftsmanship |

| Allen Edmonds | Port Washington, WI | Men’s Footwear & Accessories | Goodyear-welt construction |

| Saddleback Leather | Fort Worth, TX | Rugged Bags | Extreme durability & 100-year warranty |

| Filson | Seattle, WA | Outdoor Hybrids | Unfailing goods (Canvas & Bridle Leather) |

| Red Wing Shoes | Red Wing, MN | Heritage Work Boots & Belts | Owns S.B. Foot Tanning Co. |

| Coach | New York, NY | Luxury Handbags | Accessible luxury & American style |

| Duluth Pack | Duluth, MN | Canvas & Leather Packs | Handcrafted, lifetime guarantee |

| Bosca | Springfield, OH | Fine Wallets & Briefcases | Hand-stained Italian leathers |

| Jack Georges | New York, NY | Business Cases | Functional, professional design |

| Moore & Giles | Lynchburg, VA | Luxury Travel Goods | Expertise in unique, premium leathers |

| Ghurka | New York, NY | Military-Inspired Bags | Artisanal, registered heirloom pieces |

| Tandy Leather | Fort Worth, TX | Leathercraft Supplies | Empowers individual makers |

| Ralph Lauren | New York, NY | Luxury Fashion Goods | Iconic American aspirational style |

| Odin Leather Goods | Texas, USA | Handcrafted Goods | Rugged, Texan aesthetic |

| Mitchell Leather | Milwaukee, WI | Custom Wallets | Expertise in Shell Cordovan |

| Holtz Leather Co. | Huntsville, AL | Personalized Goods | Mastery of laser engraving & branding |

| Cut and Stitch | New York, NY | Private Label Manufacturing | Full-service design-to-production |

| GFG Bag Manufacturer | Tennessee, USA | Custom Bags | Flexible, small-batch production |

| Portchester USA | New York, NY | High-Volume Production | Private label for major retail |

| Softline Brand Partners | California, USA | Sustainable Manufacturing | Focus on eco-friendly materials |

| Fifield, Inc. | Hingham, MA | Industrial Fabrics | Specialty non-fashion materials |

| Silver Creek Leather Co. | Indiana, USA | Leathercraft Kits & Supplies | Accessible DIY leather projects |

| American Leather Operations | Dallas, TX | Premium Furniture | Lean manufacturing & speed |

| Ezra Arthur | USA | Minimalist Wallets & Bags | Modern design with heritage quality |

Emerging Trends in US Leather Goods Manufacturing

The US leather goods industry in 2025 is being shaped by powerful trends. Key among them are eco-innovations, with a major push towards sustainable bio-leathers and circular recycling programs. Technological advancements like AI-driven prototyping are accelerating design. A growing market for material hybrids and high-quality vegan options is also emerging, while the continued rise of e-commerce and a preference for localization are boosting domestic manufacturing.

Eco-Innovations: Bio-leathers and Recycling

Sustainability is no longer a niche concern; it’s a primary driver of innovation. The industry is seeing a significant push towards a circular economy, with manufacturers developing methods to recycle leather scraps into new, durable materials. Even more exciting is the rise of bio-leathers. These are next-generation materials grown from sources like mushrooms (mycelium) or created in a lab, offering the look and feel of leather with a vastly reduced environmental footprint. US-based companies are at the forefront of this research, positioning the domestic market as a leader in green material science.

Tech Advances: AI Prototyping

Technology is revolutionizing the traditionally slow process of product development. Manufacturers are increasingly using AI and 3D rendering to create digital prototypes. This allows brands to visualize and refine their designs with incredible speed and accuracy before a single piece of leather is cut. This tech-driven approach reduces waste, shortens lead times, and allows for a more collaborative and efficient design process, giving US manufacturers a significant competitive edge.

Material Hybrids and Vegan Options

The modern consumer loves versatility, and manufacturers are responding by creating innovative material hybrids. We’re seeing more products that combine the durability of leather with the lightweight, functional properties of materials like waxed canvas, rugged twill, and high-tech synthetics. This trend, championed by brands like Filson and Duluth Pack, creates products that are both stylish and highly practical. Alongside this, the demand for high-quality, premium vegan options continues to grow, pushing manufacturers to source and perfect alternatives that offer a luxury feel without the use of animal products.

Market Growth: E-commerce and Localization

The twin forces of e-commerce and a desire for local production are creating a powerful tailwind for the US leather goods industry.

E-commerce platforms have given small, artisanal American brands a global stage, fueling a renaissance in handcrafted goods. At the same time, recent global supply chain disruptions have led many larger brands to pursue a “localization” strategy, moving production closer to home to reduce risk and ensure faster delivery. This trend is channeling new investment and demand into domestic factories, driving growth and innovation across the sector.

Challenges Facing the US Leather Goods Industry

Despite its strengths, the US leather industry faces significant challenges in 2025. These include intense overseas rivalry offering lower production costs, domestic cost pressures from inflation and labor, and a growing skills shortage in artisanal craftsmanship. Navigating these hurdles requires a focus on the key American advantages: superior quality, innovation, and a strong “Made in the USA” brand identity.

Supply Issues and Global Competition

While the US has excellent tanneries, manufacturers can still face shortages of specific types of hides or hardware, which may need to be sourced globally. This exposes them to the same international supply chain vulnerabilities as overseas producers. The primary challenge, however, is the intense competition from countries with significantly lower labor and regulatory costs, which can offer a much lower price per unit.

Cost Pressures and Inflation

Manufacturing in the USA is inherently more expensive. Higher labor wages, stricter environmental regulations, and the rising costs of domestic raw materials all contribute to a higher final product cost. Inflationary pressures can further squeeze profit margins, making it challenging for US manufacturers to compete on price alone with their international counterparts.

Overseas Rivalry and the Quality Counter

The biggest challenge for US manufacturers is the cost advantage of overseas rivals. The primary way they counter this is by focusing relentlessly on what sets them apart: superior, verifiable quality.

Brands that choose to manufacture in the US are not looking for the cheapest option; they are looking for the best. US factories lean into this by emphasizing their artisanal craftsmanship, their use of premium domestic materials, and their commitment to ethical production. This “quality counter” is their most powerful weapon against the lower prices offered abroad.

The Skills Shortage

As experienced leatherworkers from older generations retire, there is a growing concern about a skills shortage in the industry. The intricate, hands-on techniques of leathercraft are not easily replaced by automation. This has led to a renewed focus on workforce training and apprenticeship programs to ensure that the tradition of American craftsmanship can be passed down to a new generation of artisans.

How to Build a Successful Partnership with a US Leather Goods Manufacturer

Building a successful partnership with a US manufacturer hinges on clear communication and a collaborative mindset. Start with a detailed RFQ and sample evaluation to set clear quality standards. Focus on building a relationship that allows for open feedback on design and production. Ensure your contract is comprehensive, covering everything from ethical audits to logistics. A strong partnership is built on mutual respect and a shared commitment to quality.

Effective Outreach Strategies

Your first impression matters. Approach potential partners with a professional and detailed Request for Quotation (RFQ) that includes your tech packs, material specifications, and estimated order quantities. This shows you are a serious and organized potential client. Once you’ve made contact, requesting samples is the crucial next step. A willingness to invest in prototyping demonstrates your commitment and allows you to evaluate their quality firsthand.

Collaboration and Feedback

The best manufacturing relationships are collaborative. Don’t just hand over a design and expect a perfect product. Engage with your manufacturer. Be open to their feedback on materials or construction techniques—they are the experts and can often suggest improvements that enhance quality or reduce cost. Establish a clear and consistent feedback loop throughout the design and sampling process to ensure you are both aligned on the final vision.

Ethical and Sustainable Focus

Make your commitment to ethical and sustainable production clear from the start. Discuss their certifications and ask to see their social compliance audits. A manufacturer like Hoplok Leather, which holds certifications like SMETA and BSCI, will welcome this conversation. Aligning on these values is a critical component of a modern, resilient partnership.

Contracts, Logistics, and Negotiation

Your manufacturing agreement is the foundation of your partnership. It should be detailed, clear, and mutually beneficial, protecting both parties and setting clear expectations for a successful production run.

Work with your partner to negotiate fair terms that cover everything from pricing and payment schedules to quality standards and delivery timelines. Discuss logistics upfront to ensure a smooth process. A transparent and comprehensive contract is the key to a stress-free and successful manufacturing experience.

Why Choose Hoplok Leather as Your Best Leather Goods Manufacturer and Supplier

Hoplok Leather stands out as an ideal partner by blending over 22 years of global manufacturing experience with a strong US-based design and management team. They offer the best of both worlds: the cost-effectiveness and scale of their international production facilities combined with the quality control, communication, and ethical standards expected by American brands. Their expertise in custom, private-label production makes them a premier choice.

Company Overview and 2025 Highlights

With a rich history spanning more than two decades, Hoplok Leather has established itself as a premier global manufacturer of custom leather goods. While their production facilities are strategically located in Cambodia and China to ensure cost-effectiveness, their management and design teams include US-based experts, ensuring a deep understanding of the American market’s quality and style expectations. In 2025, Hoplok is focused on expanding its sustainable material lines and leveraging its advanced custom capabilities to help brands innovate faster.

Unique Strengths: The Best of Both Worlds

Hoplok offers a unique value proposition that few can match. Brands partnering with Hoplok benefit from:

- Premium Craftsmanship: A blend of traditional techniques and advanced technology ensures every product is crafted to the highest standards.

- Ethical Sourcing & Production: With full control over their supply chain and internationally recognized certifications (ISO9001, SMETA, BSCI), they guarantee ethical and responsible manufacturing.

- Innovation and Flexibility: Their expertise in sourcing a wide range of materials, including vegetable-tanned leathers and other sustainable options, allows for deep customization.

Product Range and Customization

Hoplok is a full-service, private-label specialist. They don’t just produce a standard catalog; they bring your vision to life. Their capabilities cover a vast range of products, including handbags, wallets, belts, and backpacks. A key advantage for emerging brands is their flexible MOQ, which allows for smaller, more manageable production runs. This, combined with rapid prototyping (as fast as 2-7 days), empowers brands to be agile and responsive to the market.

Customer Benefits and A Call to Partnership

For a brand seeking a partner that offers the quality and ethical assurance of a top-tier manufacturer with the speed, flexibility, and cost-effectiveness of a global leader, Hoplok Leather is the ideal choice.

The benefits are clear: rigorous quality assurance at every stage, factory-direct pricing that boosts your profit margins, and comprehensive support from design consultation to global logistics. They have a proven track record, having served over 1,500 companies, including global brands like GUESS and J.CREW. To begin your partnership, simply reach out for a free design consultation. Their 24/7 customer service ensures a responsive and collaborative experience from day one.

Frequently Asked Questions (Based on Google PAA)

Common questions focus on identifying top manufacturers and making the right choice. The top manufacturers include heritage tanneries like Horween, artisanal brands like Tanner Goods, and versatile partners like Hoplok Leather. Choosing a supplier involves a clear, step-by-step process of research, sampling, and auditing. A key trend is the move towards sustainability, with many US manufacturers offering eco-friendly options.

Who are the top leather goods manufacturers in the USA?

The top manufacturers include a mix of heritage tanneries like Horween Leather Company, artisanal brands known for direct-to-consumer quality like Tanner Goods and Saddleback Leather, and expert private-label manufacturers like Cut and Stitch. The “best” depends on whether a brand needs raw materials, a finished product line, or custom production.

What are the best American-made leather brands?

Brands renowned for their American-made quality include Filson for rugged outdoor gear, Allen Edmonds for classic footwear, and smaller artisanal makers like Odin Leather Goods. For brands looking to create their *own* line, a manufacturing partner like Hoplok Leather provides the expertise to build a top-tier, American-designed product.

How to choose a leather goods supplier in the USA?

Follow a clear, six-step process: 1. Assess your needs (product, volume, budget). 2. Research and shortlist potential partners. 3. Evaluate samples to verify quality. 4. Conduct facility audits for ethical and production standards. 5. Negotiate a detailed contract. 6. Focus on building a strong, long-term partnership.

What trends are shaping the US leather industry?

The key trends in 2025 are sustainability (eco-friendly tanning and bio-leathers), technology (AI prototyping), a move towards localization to shorten supply chains, and the continued growth of e-commerce for artisanal brands.

Are US leather manufacturers sustainable?

Yes, many US leather manufacturers are highly sustainable. They operate under strict environmental regulations and are increasingly adopting practices like vegetable tanning and water recycling. Companies like Hoplok Leather further demonstrate this commitment with certifications like SMETA, ensuring ethical and environmentally conscious production.

Conclusion

The American leather goods manufacturing landscape in 2025 is vibrant, diverse, and full of opportunity. From century-old tanneries to innovative, service-driven partners, the 25 companies on this list represent the pinnacle of quality, craftsmanship, and resilience. Choosing to manufacture in the USA offers brands a powerful advantage in a market that increasingly values quality, transparency, and a compelling story. The key is to find a partner who not only has the right technical capabilities but also shares your vision and values.

As you begin your journey, we encourage you to use this guide as a starting point. Do your research, ask the tough questions, and prioritize building a strong, collaborative partnership. For brands seeking a manufacturer that embodies the best of both worlds—combining deep global experience with the quality standards and design sensibilities of the US market—we invite you to connect with us at Hoplok Leather. Let us show you how our expertise can help bring your vision to life and build a brand that stands the test of time.

Ready to Build Your American-Designed Leather Goods Line?

Finding the right manufacturing partner is the most important step in your brand’s journey. At Hoplok Leather, we combine over two decades of global manufacturing excellence with a US-based team to offer unparalleled service, quality, and value. Let us be the expert partner that helps you succeed.